ESSERT

Picking transparent syringes in the pharmaceutical industry enabled by 3D machine vision

Bin-picking

Pick and Place

Material handling

ESSERT Robot Retrayer

ABB YuMi dual-arm cobot

Pickit 3D Vision System

Zivid One+ 3D camera

ESSERT Robotics

Germany

01 Overview

Automation is an essential element in the pharmaceutical manufacturing industry as it helps maximize productivity and reduce errors. To pick and place transparent syringes precisely and quickly, ESSERT developed an industrial robot workstation with the ABB YuMI cobot. To fulfill the hiqh-quality vision requirements, ESSERT partnered with Pickit for their robot cell bin-picking solution, including Zivid One+ 3D color camera.

Quick facts

Company

ESSERT

Vision System

Pickit M-HD

Application

Transparent syringes

Pick and place

Features

ABB YuMi dual-arm cobot

Material handling

Bin-picking

Modular robot cell

3D machine vision system

3D camera

Zivid One+

Published

24 Aug 2020

We are now able to recognise small, transparent syringes with fast cycle times – around four seconds to pick and place each syringe. This is ideal, as, if you are looking to automate an application, you must have a cycle time below 10 seconds.

Tobias Claus

Pickit

02 Background

ESSERT is a robotic company founded in 2009 and based in Ubstadt-Weiher, Germany. The company designs modular and flexible robot workstations that enable human-robot collaboration for various manufacturing companies. Vetter, a leading manufacturer for pharmaceutical packaging solutions, approached ESSERT for a new solution to automate the packaging process of transparent syringes.

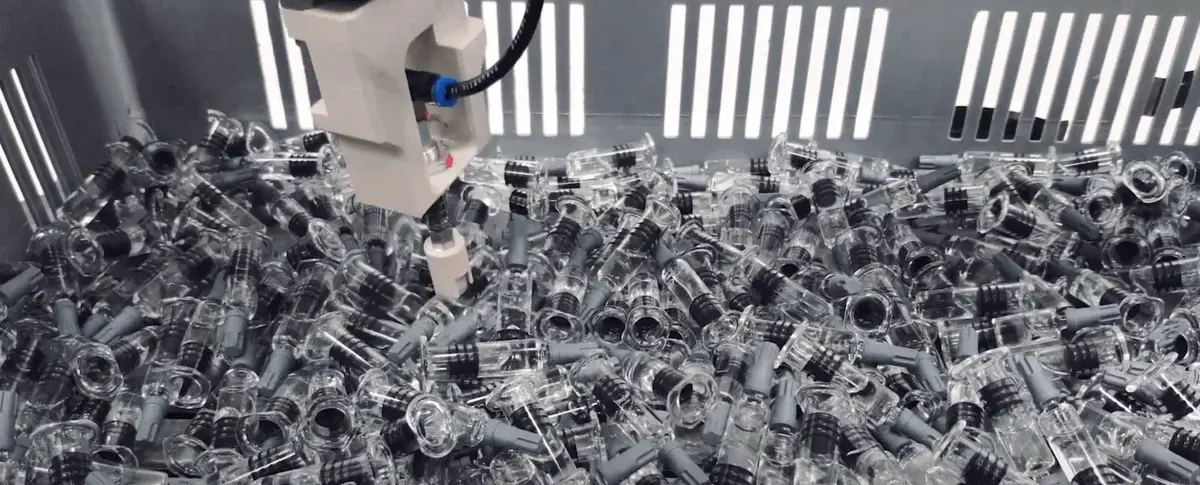

Transparent syringes are provided in a tote box before they are sorted and packed. Each syringe needs to be picked and placed correctly into the shipping tray from their random position in the box. This 24/7 process can be very costly and time-consuming when performed manually.

The new automation system's goal was to detect, select, pick, and place individual transparent syringes within a few seconds with minimum manual interference.

03 Challenges

ESSERT's robot cell needed an advanced 3D machine vision to enable a reliable bulk syringes' bin-picking operation. One of the challenges was how to handle the transparent property of the syringes. With unclear edges and overlapping features, transparent materials are considered impossible or one of the toughest challenges for machine vision applications.

Ensuring a reliable and fast production cycle introduced another challenge. The YuMi robot had to complete each pick and place within a few seconds to meet the increased demand for medical devices. As a result, the machine vision system detects a target object, generates a 3D image (point cloud), and calculates the correct pick position in less than a second.

04 Solution

ESSERT decided to collaborate with Pickit, a 3D machine vision system provider, for handling the transparent syringes. Fortunately, each syringe includes a black, reflective feature, which helps the system identify each object. Pickit’s M-HD machine vision system, which includes a Zivid One+ 3D camera, was chosen to solve the bin-picking challenges, as the high-accuracy 3D camera is designed to detect small objects.

The Zivid One+ 3D camera uses a 2.3 MPixels image sensor. It can capture both RGB color, 2D, and 3D simultaneously, and enable Pickit to process high-quality 3D point clouds. With Pickit’s 3D vision software, developers can easily set up the robot cell with a machine vision system and run calibration tools without minimal experience. Finally, the short cycle time targets were met using the fast acquisition time of the 3D camera.

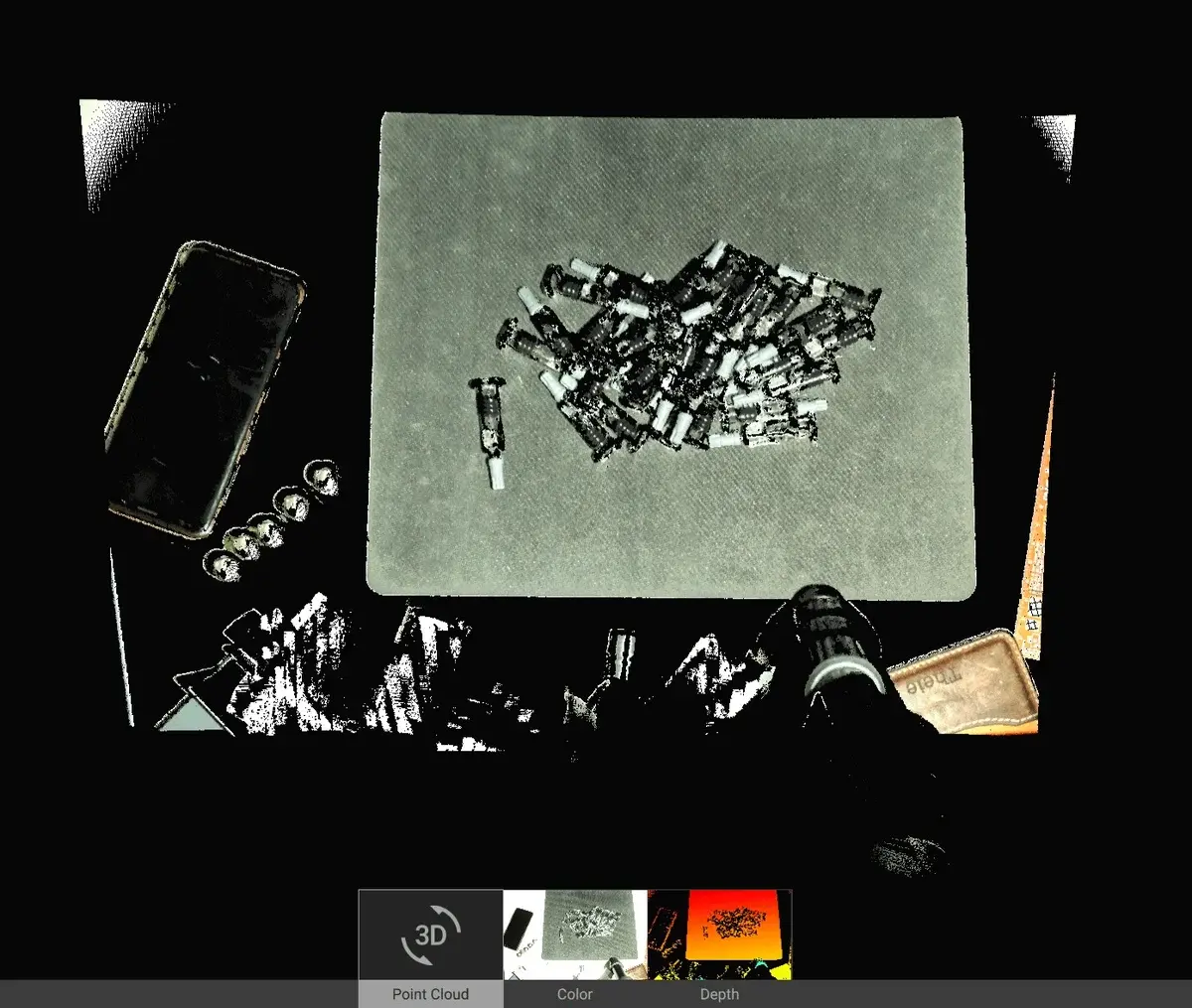

Below is an example point cloud of transparent syringes. The Zivid One+ 3D camera captures transparent syringe clearly, even though they are overlapped.

05 Result

ESSERT introduced the Retrayer edition, an advanced robotic workstation solution designed for the pharmaceutical industry. With Pickit’s H-MD 3D machine vision technology, they were able to perform tasks that were not possible earlier.

The picking station solution includes an ABB YuMi cobot with dual grippers for detecting, picking, and correctly placing transparent syringes in 4 seconds. The robot cell can be retrained to handle various medical devices and materials for a fully or partially automated work environment.

ESSERT’s flexible robotic workstation with cutting-edge 3D vision solution opens up a new opportunity for pharmaceutical companies that need to handle challenging objects. Their automation solution will help the companies to meet the demand in the rapidly growing pharmaceutical market reliably.

About Pickit

Pickit is the 3D robot vision solution that guides your robot to pick and place a wide range of products to automate your processes in a flexible way. → www.pickit3d.com

Zivid One+ 3D color cameras

- Zivid One+ Small - suitable for very small objects

- Zivid One+ Medium - suitable for small to medium objects

- Zivid One+ Large - suitable for medium to large objects