3D vision for the manufacturing industry

Improved Object Recognition

High-resolution, ultra-precise native 3D point clouds enable robots to enhance object recognition and detect a greater number of parts with increased reliability.

Reliable 3D Picking Accuracy

3D vision allows for dependable object boundary detection by accurately capturing an object’s size, orientation, and absolute position.

Accurate Placement and Orientation

Vision-guided robots can perform precise pick-and-place tasks, ensuring correct placement and orientation while avoiding collisions and potential damage.

Point cloud examples of manufacturing objects captured with a Zivid 3D camera

What's possible with Zivid 3D cameras

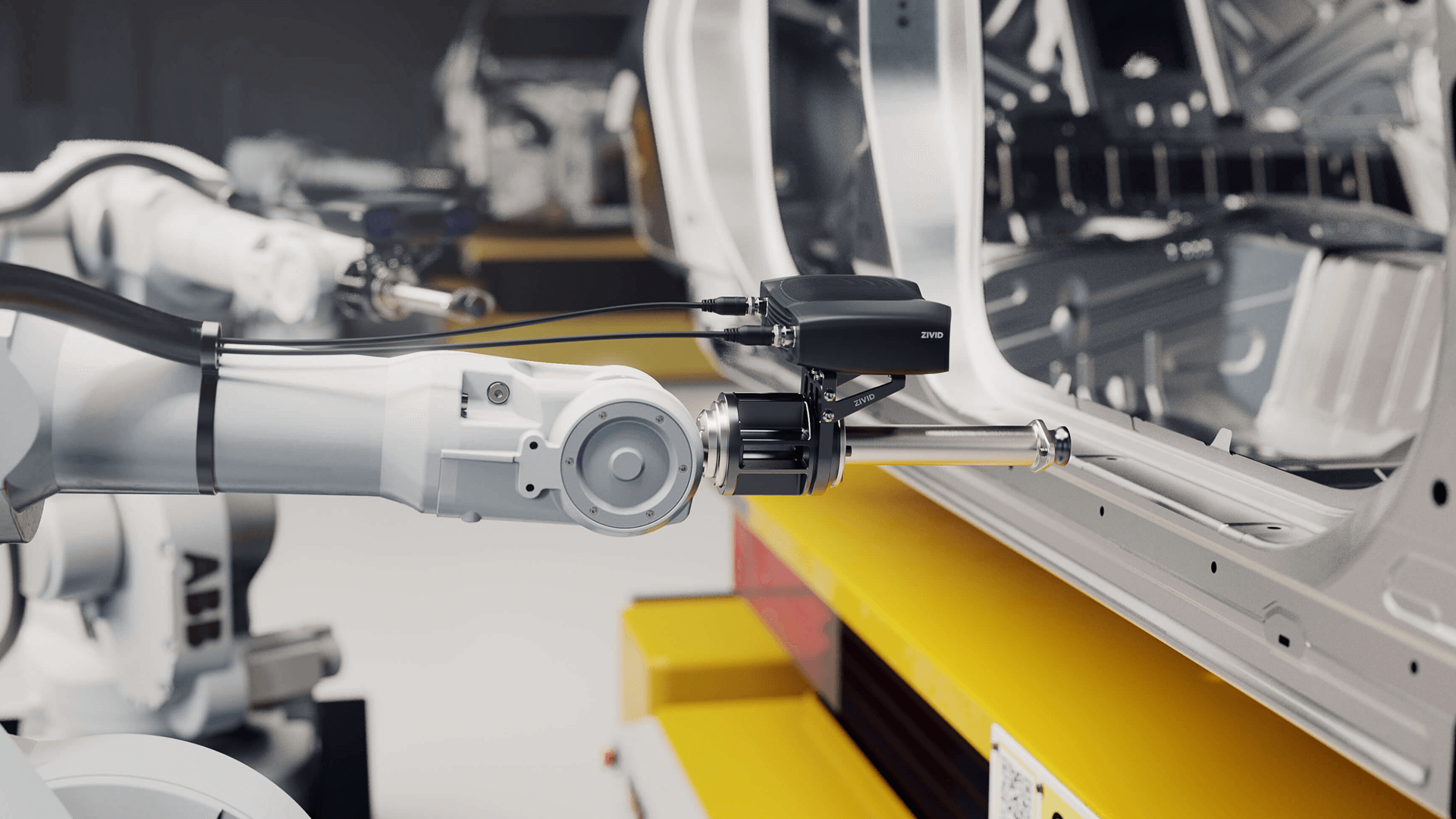

Robot-Guided Welding, Gluing, and Surface Finishing

In manufacturing, precision is everything. The Zivid 3D camera guides your robot with sub-millimeter accuracy, enabling it to follow traces, contours, and shapes just like a skilled human operator. It captures materials other vision systems can't, delivering true-to-reality point clouds for a range of surfaces and finishes.

Zivid is the ultimate 3D camera for robotic guiding, ensuring faster execution and consistent, high-quality results. It also delivers high-definition, full-color images in both 2D and 3D point clouds, detecting fine details with human-like perception.

Assembly

Allow your robot to fasten screws, tighten bolts, insert connectors and join complex parts where the tolerance for error is small. Zivid produces incredibly dense, precise and accurate point clouds, whether you are dealing with black plastics, complex shapes or shiny metallic objects. With its powerful sensor and the revolutionary reflection filters, Zivid handles reflections and captures tiny holes, screws and cables at a completely different level from a close distance.

Check and inspect

Zivid excels in delivering the very highest quality point clouds with exceptional trueness. Make highly accurate measurements of object dimensions, form, depth, and height with factory-calibrated dimension trueness of > 99.8 % and simple and effective calibration tools.

Combining high-resolution point clouds with the sharpest colored 2D images of its class, Zivid lets you mix and match inspection algorithms to achieve the correct result.

Customer Stories

Graymatter Robotics | AI-powered robotic surface finishing

GrayMatter integrated the Zivid camera into their AI-powered robotic cells, enabling precise, color-accurate 3D scanning for surface finishing applications.

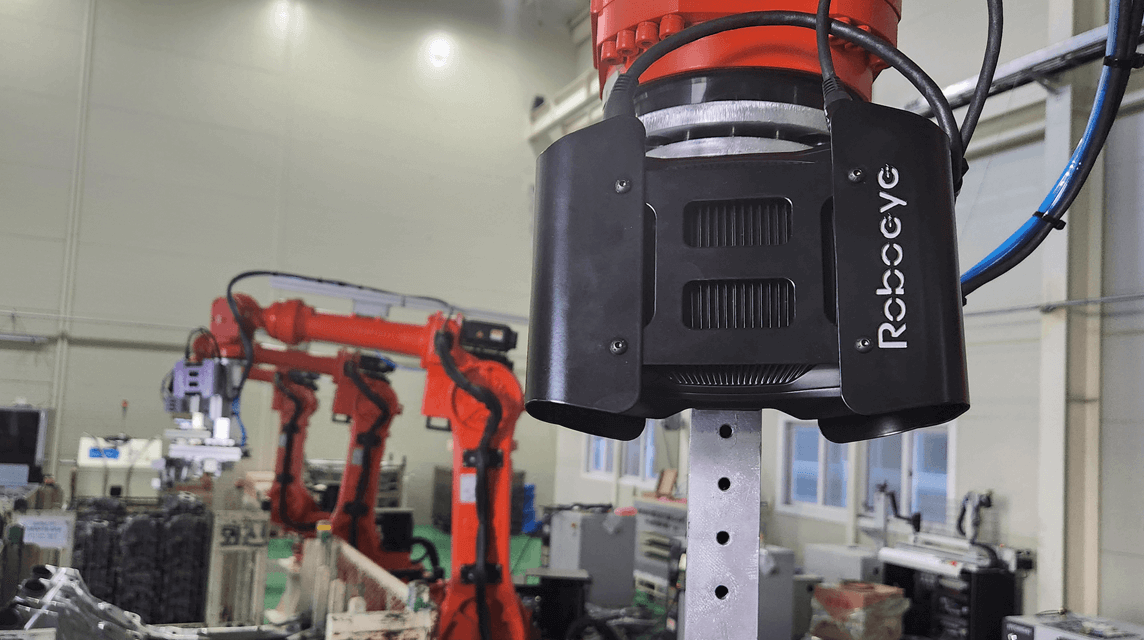

ING Robotics | 3D vision solution for manufacturing

ING Robotics introduced ROBOEYE, a 3D vision solution combining the Zivid 2+ L110 3D for precision assembly automation.

%20(1).png?width=1920&height=1080&name=MR60_nr.5_assembly%20(2)%20(1).png)

.png?width=1920&height=1080&name=MR60_nr.5_assembly_zoomed%20(1).png)