What is industrial inspection?

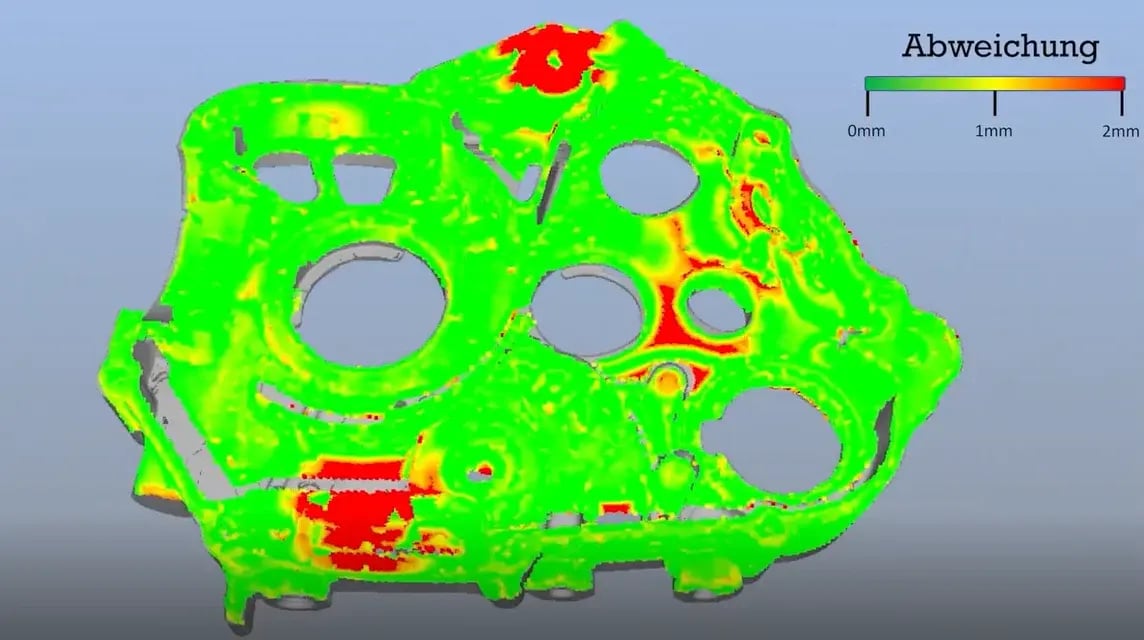

Inspection point cloud captured with a Zivid 3D camera, featured in our webinar: Exploring Manufacturing Applications with Advanced 3D Vision Technology.

Automated industrial inspection focuses on detecting critical details across a wide range of industrial equipment and machinery. This process demands the reliable capture of high-resolution 3D point clouds and exceptional trueness performance, even in challenging industrial environments. Inspections may involve identifying cracks, wear, damage, or verifying the presence or absence of key components essential to operational efficiency and safety.

3D vision in industrial inspection

Precise Detail Analysis

Capture highly accurate measurements of object dimensions, shapes, colors, depth, and height using advanced 3D vision technology.

Flexible 3D Positioning

Inspect objects from multiple angles and viewpoints to eliminate blind spots, reduce occlusion, and minimize point cloud artifacts.

Consistent, Repeatable Results

Industrial-grade 3D vision systems ensure reliable and repeatable performance, even in the most demanding inspection environments.

Why use a Zivid camera?

Can you see the difference?

High-Precision 3D Vision

Robotic inspection demands precise, consistent vision to detect fine details and verify components with sub-millimeter accuracy. From wheel profiling to weld seam checks and bolt placement, performance depends on what the robot can see.

Zivid 3D cameras deliver high-resolution point clouds with over 99% trueness in position, size, and orientation. Advanced HDR and reflection filters ensure reliable detail capture, even in complex environments.

- Precise, autonomous defect detection

- Accurate handling of small parts in clutter

- Reliable dimension and profile verification

Flexible 3D Mounting

Robotic inspection allows robots to perform inspection and maintenance tasks in confined or hazardous environments via remote access. Achieving accurate results in these conditions requires flexible 3D vision capable of capturing high-quality point clouds from varied positions.

Zivid 3D cameras are designed for both stationary and robot-mounted use. Their compact, lightweight design and short baseline allow easy mounting on robotic arms without compromising payload capacity or maneuverability.

.png?width=2000&height=1055&name=Inspection%20with%20Zivid%203D%20vision%20(1).png)

True 3D Color Vision

Full-color 3D vision provides greater accuracy, coverage, and speed compared to 2D or monochrome systems. It’s especially valuable for inspecting varied objects in production and assembly environments.

Zivid cameras deliver high-definition color point clouds with 3D precision, enabling robots to inspect even small, similar-shaped parts with confidence. Using non-laser white light, they capture true color across a wide range of materials—including shiny, dark, and textured surfaces.

Other 3D vision solutions

❌ The robot has difficulty handling a wide variety of objects, especially small items such as screws.

❌ The vision system struggles to capture complete point clouds on highly reflective or black materials due to imaging artifacts.

❌ The robot cannot clearly identify parts and their boundaries and find the optimal pick point.

❌ The 3D camera is not suitable for robot-mounted use.

❌ Camera lacks true industrial grade robustness and struggles with stability.

With Zivid 3D camera

✅ The robot can capture millimeter level detail with high accuracy.

✅ The vision system can handle a wide variety of challenging items and materials, including shiny metallic parts.

✅ The robot can clearly identify a parts shape and its position to find the ideal pick pose.

✅ Zivid 3D cameras are comfortable and excel when mounted on the robot.

✅ Delivers ultra-stable 3D data with near total immunity to ambient light levels.

Customer Stories

Pandia Pure democratizes quality control inspection

Pandia Pure together with Zivid 3D cameras bring a very high-quality assurance inspection capabilities to anyone at a very competitive price point.

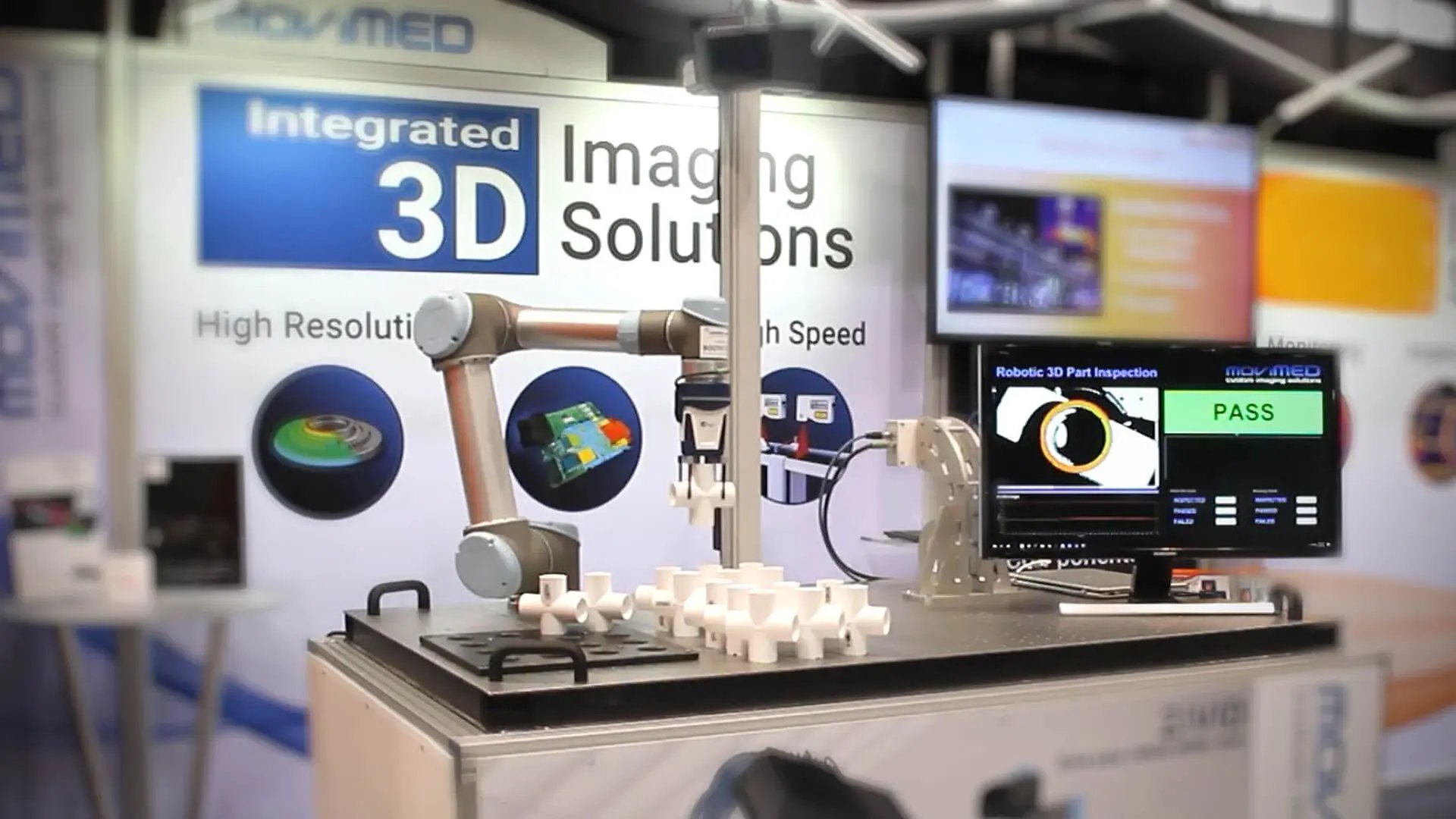

MoviMED's 3D inspection

Collaborative pick & place paired with inspection and verification.

-1.webp?width=1144&height=640&name=Untitled%20(1144%20%C3%97%20614px)-1.webp)

Urban Machine | Robotic solution recycles lumber

"The Machine" is an automated solution that uses Zivid 3D to reclaim lumber and salvage the past to build the future.