What is automated assembly?

Automated assembly demo by Mujin using a Zivid 3D camera

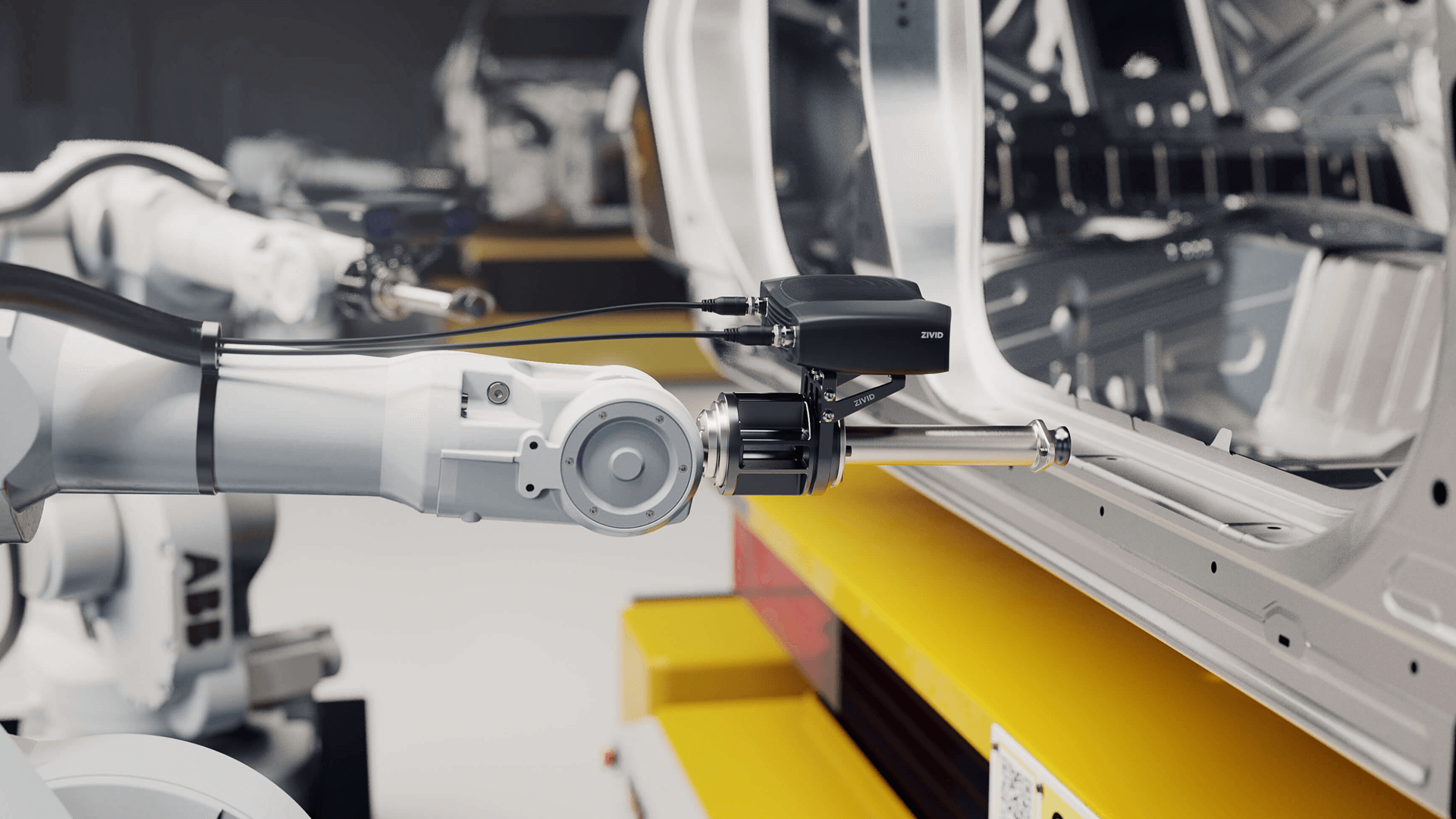

Robotic assembly demands high-precision part picking and manipulation. Tasks can range from basic pick-and-place operations to more complex processes like part insertion and fastening. Industrial assembly often involves rigid metal components and relies on robots with low-compliance grippers, making precision and reliability critical. These applications are among the most challenging for robotic systems, especially those that depend on 3D vision for accurate alignment and execution.

Zivid 3D vision cameras are purpose-built for assembly automation, delivering the accuracy, reliability, and efficiency required to meet the demands of modern manufacturing.

3D vision in automated assembly

Capture every detail

A 3D vision camera captures highly detailed, accurate, and complete point clouds, even for small, reflective, and complex assembly parts.

Flexible positioning

Placing the 3D camera at the optimal distance and angle improves capture quality and allows the robot to operate across multiple workspaces.

Reliable in industrial environments

Industrial-grade 3D vision cameras provide consistent performance, both in demonstration cells and in demanding manufacturing settings.

Why use a Zivid camera?

Can you see the difference?

Accurate 3D vision for challenging parts

Detecting small, stacked, and shiny parts is difficult because robots struggle to capture enough detail for reliable assembly operations. This task requires a complete point cloud that accurately represents the scene, without holes or missing data.

Zivid 3D cameras deliver high-resolution point clouds with over 99% accuracy in position, size, and orientation. With advanced HDR and reflection filters, they handle even the most challenging parts in industrial environments.

Autoracking assembly application with SIDASA and INNODURA

Flexible 3D Vision for Precise Robotic Assembly

An assembly robot cell must operate flexibly within the robot’s working range to achieve precise three-dimensional positioning. This requires a 3D camera mounted on the robot itself, enabling it to view the scene directly ahead.

Zivid cameras are designed for both stationary and robot-mounted setups. Their short baseline and lightweight design deliver high-definition point clouds without impacting the robot’s payload capacity or maneuverability.

Built for Industrial Reliability

Your 3D vision camera must deliver consistent performance in industrial assembly environments without compromising long-term reliability. Assembly settings pose challenges such as vibrations, temperature changes, dust, and varying lighting conditions.

Consumer-grade cameras typically cannot withstand these demands. Industrial-grade Zivid 3D cameras undergo rigorous endurance testing to ensure reliable performance under real-world factory and robot assembly conditions.

Other 3D vision solutions

❌ Insufficient dynamic range prevents capturing complete point clouds of the workpiece.

❌ Struggles with highly reflective or dark materials due to imaging artifacts.

❌ A statically mounted camera cannot image from optimal positions or angles.

❌ Harsh working environments hinder reliable 3D camera calibration.

With Zivid 3D camera

✅ Capture detailed point clouds in hundreds of milliseconds without affecting robot performance.

✅ Obtain highly accurate and complete point clouds on shiny metals and deep black parts.

✅ Always image the workpiece from the optimal distance and position.

✅ Proven to perform reliably in the most demanding industrial environments.

Customer Stories

Automotive assembly with CMES

CMES fuse deep learning with 3D machine vision to change the face of automotive assembly.

-2-2.webp?width=1144&height=640&name=Untitled%20(1144%20%C3%97%20614px)-2-2.webp)

Innodura's complex parts hanging solution for assembly lines

Hanging parts for processing is a task that has been primarily carried out manually, and automating it has proven to be a real challenge.

-1.webp?width=1920&height=1080&name=Scenario%20Automated%20Assembly%20with%20Zivid%20Two%203D%20camera%20-%20White%20Goods%20(1)-1.webp)

%20(1).png?width=1920&height=1080&name=MR60_nr.5_assembly%20(2)%20(1).png)

.png?width=1920&height=1080&name=MR60_nr.5_assembly_zoomed%20(1).png)