What is robot guidance?

Autonomous sanding of complex shapes demo by GrayMatter Robotics, using a Zivid 3D camera.

Robot guiding refers to the use of robots, equipped with high-quality 3D vision systems, to perform skilled tasks traditionally carried out by humans, with comparable levels of precision and quality. It includes processes such as welding, metal-based additive manufacturing, and complex surface treatment and finishing operations. These tasks often involve parts with intricate geometries, commonly found in manufacturing and assembly lines.

To handle such challenges, robot guiding demands advanced, human-like capabilities, including highly accurate and flexible 3D sensing mounted directly on the robot.

3D vision in robot guidance

Capture every detail

Achieve highly detailed, accurate, and complete point clouds - even for small, reflective, and complex manufacturing parts.

Flexible positioning

Positioning the 3D camera at the optimal distance and angle improves capture quality and enables the robot to operate across multiple workspaces.

Reliable in industrial environments

Industrial-grade 3D vision cameras deliver consistent performance, even in hot, particle-dense, and challenging environments.

Why use a Zivid camera?

Can you see the difference?

3D vision for complex industrial surfaces

Industrial robot-guiding often involves challenging materials, from reflective metals to deep black plastics. These surfaces require a vision system with high dynamic range and the ability to capture complete, detailed point clouds.

Zivid 3D cameras deliver high-resolution point clouds with over 99% trueness in position, size, and orientation. With advanced HDR and reflection filters, they handle even the toughest surfaces in industrial settings.

Automated welding demo with RAMLAB and TechMan Robot

Precision on the move

A robot-mounted 3D camera moves with the robot, capturing high-quality point clouds from the ideal position for millimeter-accurate welding and surface finishing.

Zivid cameras, designed for both stationary and mobile use, feature a short baseline and lightweight design that preserve payload capacity and maneuverability—enabling precise motion along complex robot-guided paths.

Built for Industrial Reliability

Industrial robot-guiding faces tough challenges, from hard-to-image materials to harsh environments like high temperatures, dust, and vibration. Cameras must stay calibrated over long periods to meet production goals.

Zivid 3D cameras are industrial-grade, built to endure these conditions:

- IP65 rated for dust and water resistance

- Floating calibration for stable accuracy

- Robot-mounted accessories for flexible use

Other 3D vision solutions

❌ Insufficient dynamic range prevents capturing complete point clouds of the workpiece.

❌ Struggles with highly reflective or dark materials due to imaging artifacts.

❌ A statically mounted camera cannot image from optimal positions or angles.

❌ Harsh working environments hinder reliable 3D camera calibration.

With Zivid 3D camera

✅ Capture detailed point clouds in hundreds of milliseconds without affecting robot performance.

✅ Obtain highly accurate and complete point clouds on shiny metals and deep black parts.

✅ Always image the workpiece from the optimal distance and position.

✅ Proven to perform reliably in the most demanding industrial environments.

Customer Stories

Graymatter Robotics | AI-powered robotic surface finishing

GrayMatter integrated the Zivid camera into their AI-powered robotic cells, enabling precise, color-accurate 3D scanning for surface finishing applications.

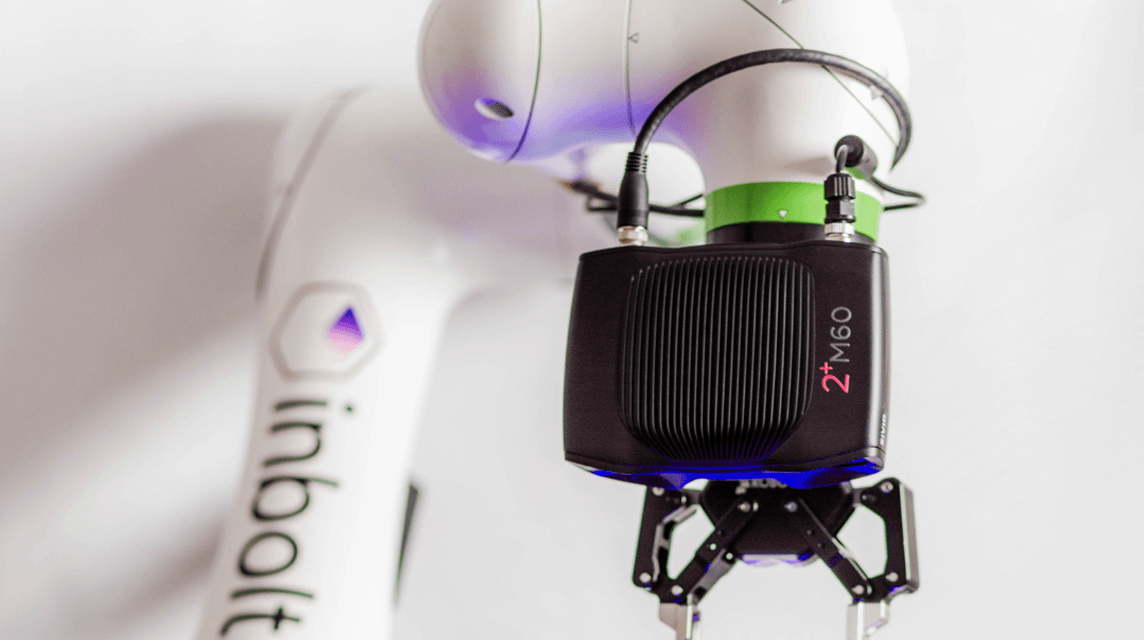

Inbolt | Flexible high-precision solution for robot guidance

GuideNOW is a vision-based robot guidance solution with astonishing precision.

.jpg?width=1920&height=1080&name=ramlab_11zon%20(1).jpg)