3D vision for the automotive industry

Improved Object Recognition

High-resolution, ultra-precise native 3D point clouds enable robots to enhance object recognition and detect a greater number of parts with increased reliability.

Reliable 3D Picking Accuracy

3D vision allows for dependable object boundary detection by accurately capturing an object’s size, orientation, and absolute position.

Accurate Placement and Orientation

Vision-guided robots can perform precise pick-and-place tasks, ensuring correct placement and orientation while avoiding collisions and potential damage.

Point cloud examples of automotive objects captured with a Zivid 3D camera

What's possible with Zivid 3D cameras

Precision for Reflective Automotive Parts

Highly reflective car components like sheet metal and polished parts challenge most vision systems. Zivid 3D cameras overcome this with advanced HDR and reflection filtering, delivering accurate point clouds for precise and reliable pick-and-place tasks in automotive assembly.

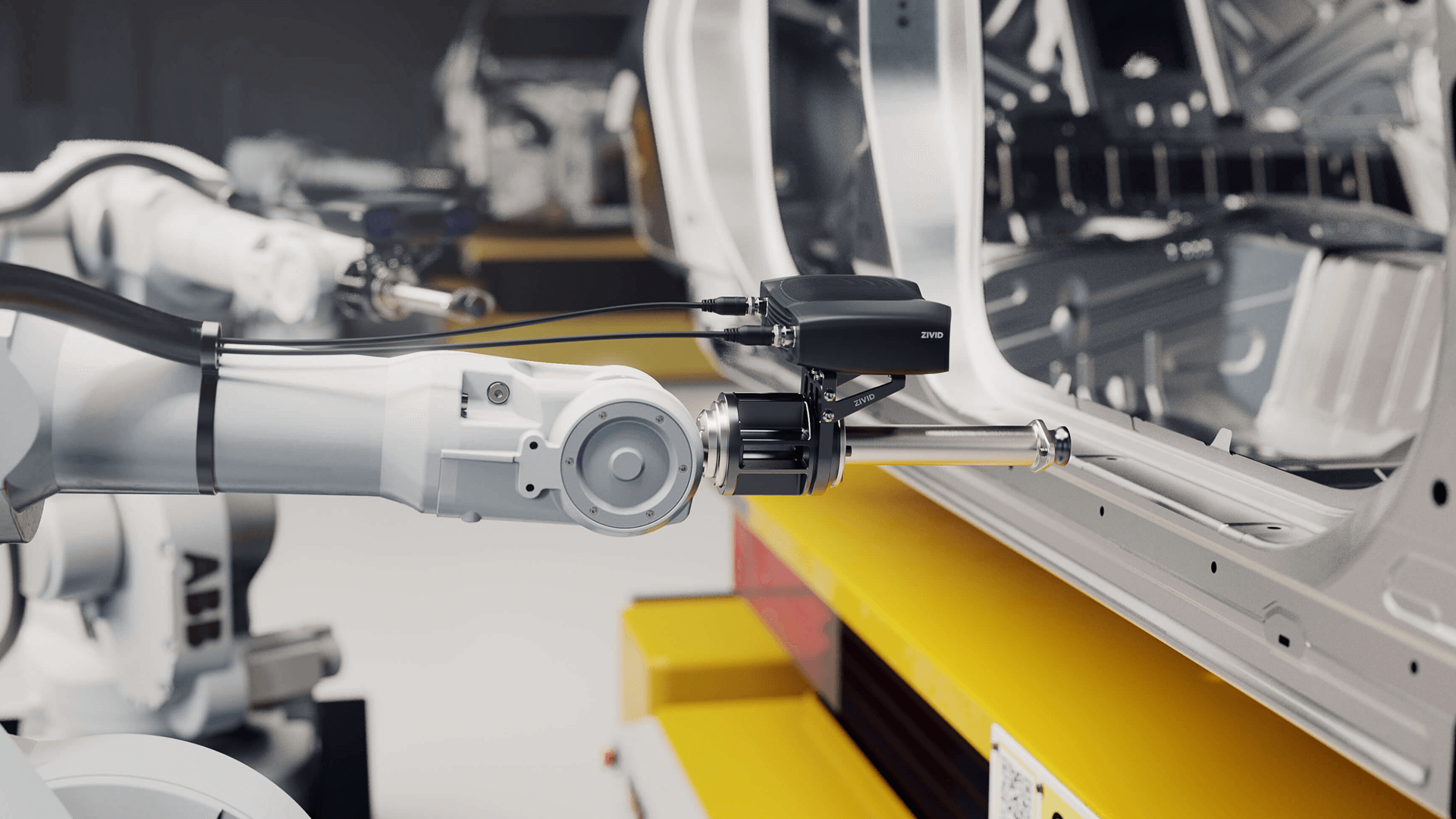

Flexible Mounting for Vehicle Inspection

Whether mounted on a robot arm or fixed station, Zivid cameras provide optimal views for every application, from interior inspections to exterior part handling. Lightweight and compact, they fit seamlessly into robotic workflows across the automotive production line.

Industrial-Grade Reliability

Automotive environments are demanding — with constant vibration, fluctuating temperatures, dust, and dynamic lighting.

Zivid 3D cameras are built to perform reliably under these conditions, offering high point cloud accuracy and stable calibration for consistent results in demanding production settings.

Customer Stories

.webp?width=1400&height=788&name=Untitled%20design%20(1).webp)

Pickit | Automotive surface finishing application

Pickit Korea remove troublesome dust spots in automotive surface finishing using a robot-mounted 3D camera.

CMES | Automotive Assembly

CMES fuse deep learning with 3D machine vision to change the face of automotive assembly.