Industrial-Grade Toughness

-

More

Industrial design

Close

Purposedly designed, built, and tested to ensure minimal trueness drift and variation under mechanical stress from handling and daily use. -

More

Shock resistance

Close

Designed for industrial use. Lightweight magnesium housing, ruggedized all-glass optics, 15G shock & 5G random vibration, 0° to 45°C operating temperature range, IP65. -

More

Continously evolving

Close

Easily roll out new innovations. With regular firmware and software updates, you can always use the latest features and performance improvements. -

More

Thermal stability

Close

Floating thermal calibration ensures minimal trueness drift and data output variations across the full operating temperature range.

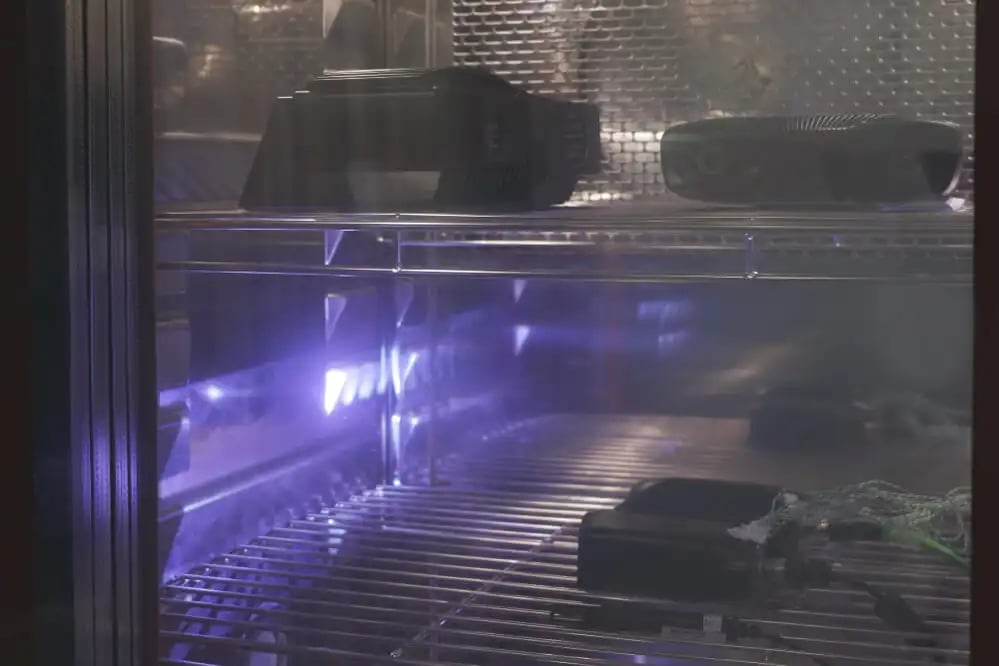

Tested to the max

Every Zivid 3D camera goes through 100+ hours of arduous performance, reliability, and calibration tests before we ship it to you.

Ready for life on a robot

Our endurance tests replicate the real world of working life on a robot, with vibration, acceleration, and deceleration. All the while we are monitoring for specified performance levels.

5 G sinus

Horizontal and vertical vibration tests up to 15 G for longevity and build qualification.

Built to take the knocks

Tested for the shocks and knocks that happen in the real industrial world.

15 G shock

Impact tests exceed several hundred Gs during build qualification.

Calibration stability

Zivid 3D cameras stay highly calibrated even in rapidly changing thermal environments. Zivid's unique floating calibration system ensures your 3D performance is always spot on.

0° to 40°C

Temperature cycles are used to verify the temperature operating range.

Delivered in perfect shape

We ensure that your industrial 3D camera arrives ready to excel in carefully designed packaging tested to handle rough shipping. Your Zivid 3D camera arrives in the same condition as it left.

Worldwide shipping

We test our 3D camera boxes by shipping them worldwide with test equipment inside to ensure they effectively protect your Zivid 3D camera.

Lifelong peak-performance

Keep your Zivid 3D camera at its peak performance with Zivid hand-eye calibration and in-field correction.

3D hand-eye calibration

Zivid's 3D hand-eye calibration simplifies the 3D camera and robot binding process and gives you 10x better results versus comparable calibration methods.

The Zivid 3D hand-eye calibration API uses the factory-calibrated point cloud to calculate the resulting hand-eye calibration. Not only does this yield a better result, but it also does so in fewer positions. And more importantly, the result is repeatable and easy to obtain.

In-field correction

Ensure your 3D machine vision accuracy is optimal and avoid the risk of stoppage or downtime. In-field correction is a fast and straightforward way to keep your 3D point clouds always on point.

Interactive content by Flourish

Impacts and shock can distort a 3D sensor's point cloud output. In-field correction brings the 3D camera back to a calibrated state.

The in-field correction procedure is used to perform verification and trueness error correction. With dedicated calibration boards and a simple procedure, you can achieve >3x accuracy improvement and reduce downtime.

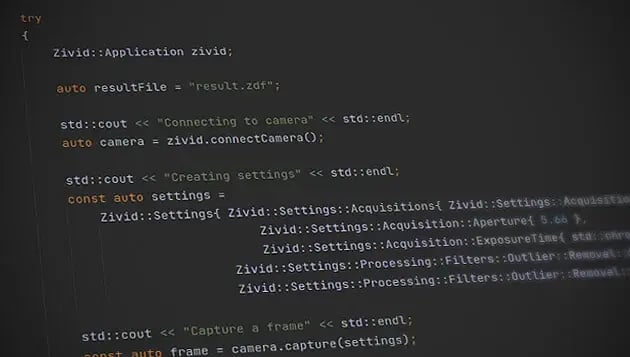

For the 3D vision developers

For the 3D developer

The Zivid SDK is designed by developers for developers.

Lifetime support

All Zivid 3D cameras include assistance from our support team.

Online knowledge base

In-depth 3D sensing knowledge, examples, and explanations.

Industrial accessories

High-quality stationary and robot-mounted mounts from Zivid.

Want to learn more?