Company

INNODURA

SIDASA Engineering

Application

Assembly and bin-picking

Features

Turn-key solution for picking, controlling, and placing pieces

AI

High-definition 3D machine vision

3D camera

Zivid 2 M70 - industrial 3D camera

Published

12 Feb 2024

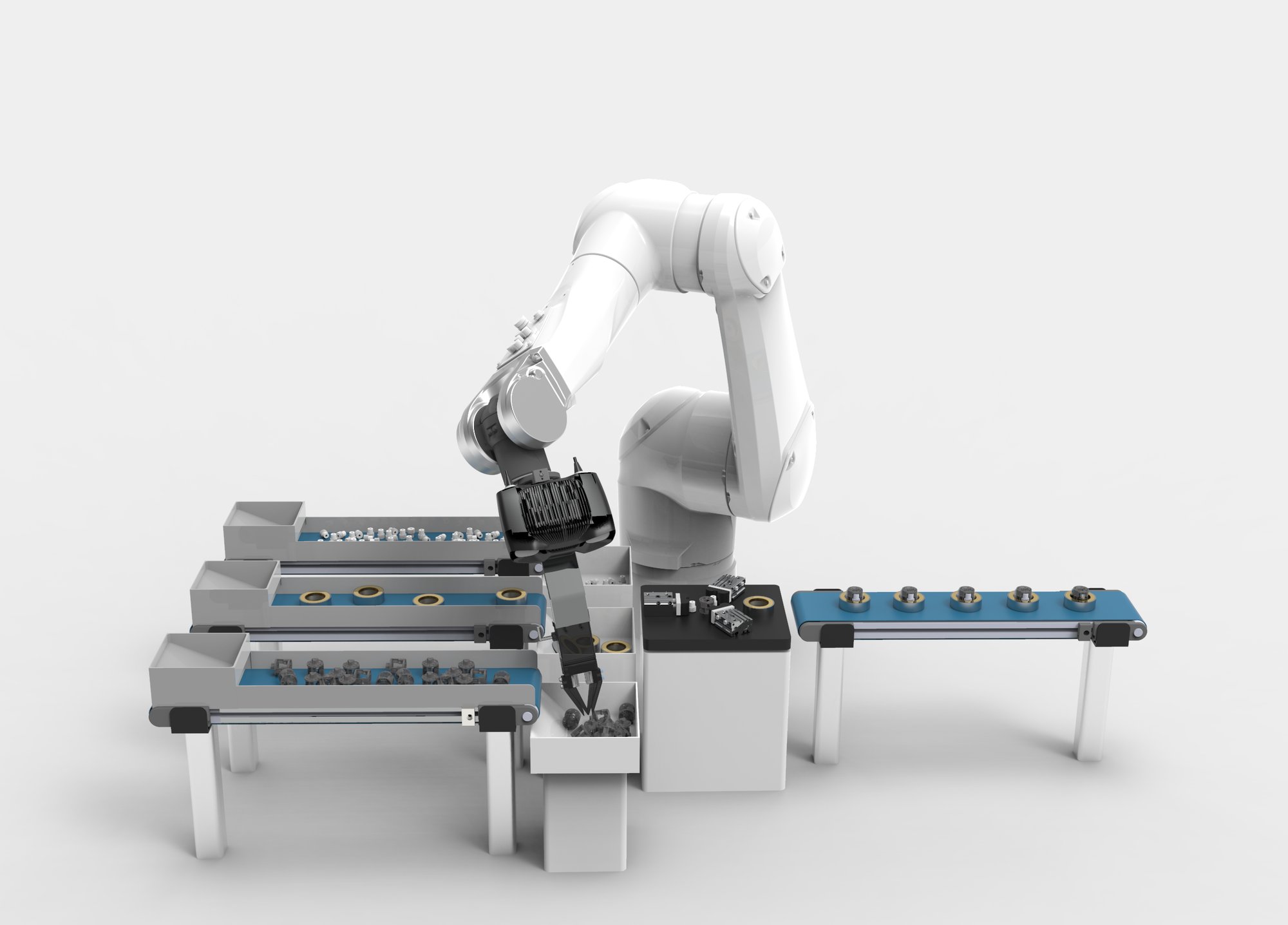

Hanging parts for processing is a task that has been primarily carried out manually, and automating this task has proven to be a real challenge. To have an adaptive solution for small and medium objects, SIDASA Engineering has designed a new technology to hang pieces on hooks using a 6-axis robot. It's a complex bin-picking and assembly application, that requires a bit of ingenuity and advanced technology to solve.

Created by INNODURA, the INNOPICK system is an adaptive robotic guidance software that has combined bin-picking, assembly, and inspection functions in the same package. This solution enables the robot to perfectly place the parts on the hooks in a single motion, at great speed. For the success of this application, INNODURA chose the Zivid 2 M70 3D camera, which returns accurate 3D point data on objects with 0.1 mm accuracy.

The InnoPICK system allows for complex industrial tasks to be performed in less than a second. SIDASA and INNODURA have achieved great success and are currently deploying their innovative solution throughout France.

The performance of the Zivid camera has enabled the creation of a complex assembly system surpassing human precision.”

Maxime Robin, CEO and Founder of INNODURA

SIDASA Engineering is one of the global leaders in integrated surface finishing. SIDASA Engineering designs and manufactures complete robotic lines. The preliminary process for surface treatment involves hanging parts on dedicated supports. This operation is mostly carried out manually. SIDASA Engineering wanted utilize a new technology to hang pieces on hooks using a 6-axis robot, with the aim of having an adaptive solution for small and medium objects.

INNODURA is an engineering company based in France, recognized for designing high-level measurement systems and developing innovative adaptive robotic solutions for the industry. The InnoPICK system, developed by INNODURA, allows for 3D bin-picking operations with great flexibility by combining 3D and AI approaches.

Hanging parts is a true challenge in robotics. SIDASA Engineering and INNODURA have come together to develop an innovative solution dedicated to these operations. From the InnoPICK bin-picking system, a new 3D computing module has been implemented. This now allows for real-time adaptation of the robot's trajectory to carry out the hanging operations of the parts on one or more hooks simultaneously.

SIDASA's bin-picking and assembly application is complex. The robot's mission is to hang parts with narrow holes onto multiple, thin hooks. The hanging frame and the hooks attached get deformed over time, changing the mechanical index of the placement location. The application needs to relocate the mechanical index to adjust the placement trajectory for each part. Thus, the system faces a complex hanging challenge with variable hooks, all combined with nonlinear trajectories. For such precision, the system requires advanced 3D technology.

Moreover, the manipulated objects are small and shiny. It is challenging for an automated system to scan reflective objects. The 3D camera must provide high resolution to cope with this additional difficulty.

In this case, the cycle time requirement varies depending on the size of the part. On average, a part needs to be placed every 5 to 10 seconds. To not alter the cycle time and the processing of the parts, it is necessary to optimize the relocation algorithms so that the system is fast. A 3D camera that can capture point clouds quickly is indispensable to this application to have minimal effect on cycle times.

Finally, the camera needs to take 3D measurements at different locations in space, whether it's the bin where the parts are located or the hooks. This requires the camera to be compact and suited for robot-mounting for more movement flexibility and to be as close as possible to the object to be scanned.

“With the Zivid camera, retrieving 2D/3D data is very simple. It is also efficient and user-friendly, allowing us to focus on high-value development tasks.”

Maxime Robin

CEO and Founder of INNODURA

Currently, few robotic systems integrate AI, assembly, and inspection solutions. The InnoPICK system is an adaptive robotic guidance software that combines those functions in the same package. This solution enables the robot to perfectly place the pieces on the hooks in a single motion, with great speed. InnoPICK can adjust the placement trajectory and adapt if the hook is deformed. Comprising a hanging module, a controller, a 3D camera, and intelligent software, this solution can be used with any type of robot.

For the success of this application, INNODURA chose the Zivid 2 M70 3D camera. The Zivid 2 M70 allows for very precise localization and digitization of small objects within a sufficiently large window to locate multiple hooks, digitizing the hooks to within 0.1 millimeters. The Zivid camera is also particularly suitable for this application as it can be mounted on the robot, allowing for close-up shots. Small in size, robust, and made of resistant materials, it is reliable in industrial environments and can be mounted on the end effector without altering its long-term performance. Moreover, the high resolution of Zivid 2 enables the scanning of shiny objects for reliable results and dense point clouds. Finally, the scanning speed of Zivid cameras has met the system's essential cycle time requirements.

Even today, many assembly and bin-picking tasks are performed by humans, as robotic systems are often very expensive and lack the necessary precision. With this application, INNODURA and SIDASA have succeeded in creating a complex hanging system, surpassing human precision and offering their customers significant time savings. Indeed, thanks to InnoPICK, it is possible to perform all these tasks in less than a second of processing time. Furthermore, this solution enables their customers to work in 3x8 shifts, reducing the risk of injuries.

New business opportunities have already been secured in France for the coming years, demonstrating the success of the system. Among these future projects, some involve larger parts, expanding the range of the working materials that the system was originally designed for. To meet this challenge, InnoPICK needs an update with a 3D camera featuring a wider field of view. For this purpose, INNODURA has chosen the Zivid 3D camera 2+ L110, which allows for object scanning at over 1 meter away with a precision of 440 µm.

INNODURA is an engineering company based in France, expert in designing measurement systems and developing innovative adaptive robotic solutions for the industry.

Zivid brings

Gjerdrums

N-0484, Oslo

Norway