Machine loading

Bin-picking

Depalletizing

Kitting and assembly

Pick and place

Company

Pickit

Location

Belgium

Application

Pickit M-HD

Picking automation

Features

Flexible solution

Robot agnostic

Hi-resolution 3D camera

3D camera

Zivid One+ Medium

Published

2 Apr 2020

Smaller, more difficult parts for automated picking, much faster part detection rates and shorter cycle times, the challenges faced by Pickit for its unique brand of off-the-shelf 3D vision-guided robot solutions were increasing. The decision to develop a smarter, higher definition product to address more exacting manufacturing demands required a more capable 3D camera. The Zivid One+ Medium camera provided the enhanced performance that was needed.

Founded in Leuven, Belgium in 2016, Pickit is a trailblazer in plug-and-play vision-guided robot solutions. Combining a 3D camera and state-of-the-art 3D vision software, pre-installed on an industrial processor, its off-the-shelf products tackle a wide range of pick-and-place applications using any brand of robot.

Emerging as a spin-out from Intermodalics, a firm developing custom software for robot control, Pickit recognised the potential in helping companies greatly simplify their manufacturing process automation. The company’s simple bold strapline, ‘Robot Vision Made Easy’ sums it up very nicely, as CEO Peter Soetens explains:

New 3D camera technology was happening, smaller collaborative robots were happening, it opened up whole new opportunities for manufacturing process automation. As a vision software specialist, we naturally set about finding a way to teach these new 3D vision-guided robots how to reliably recognise parts, how best to approach them and pick them up.

"But it was just so hard back then. Even for us – a highly qualified expert in the field – it was actually quite a struggle. So, we quickly decided to go back to basics and work from scratch, developing a standardised 3D picking software and intuitive web-like interface for customers that really was easy to use. In short, we found the missing link between 3D camera and robot."

Conception, development and thorough field-testing of Pickit’s first plug-and-play product took just three years. And since its release to market it has gone on to successfully tackle hundreds of different pick-and-place applications all around the world.

An award-winning and highly disruptive technology - in all the most positive of senses - Pickit has made 3D robotic handling far more accessible to a wider range of companies. It has meant that extensive training, experience and expertise in robot vision software is no longer a pre-requisite for using the new technology.

Pickit’s first two ground-breaking products, ‘Pickit L’: for picking large objects from pallets and bins, and ‘Pickit M’: for picking medium-sized objects from bins, boxes and tables, were warmly welcomed by the burgeoning collaborative robot market, by both end users and system integrators alike.

Integrating 3D machine vision cameras based on the principle of structured light, rather than the more problematic alternatives of time-of-flight, stereo vision and laser triangulation, Pickit was successfully addressing a broad range of pick-and-place applications in a variety of robotics-mature manufacturing sectors.

At the same time, in delivering on a commitment to provide the first truly plug-and-play 3D vision-guided robot solution that also offered the fastest return on investment, Pickit was employing high versatility cameras offering a level of image resolution sufficient to handle the widest possible application base.

The instant problem-solving success of Pickit’s first two packaged products meant the company was soon facing increasing requests for higher resolution solutions capable of tackling far more demanding pick-and-place scenarios, as Soetens explains:

Many manufacturing companies have to handle some really very small parts. These can be either plastic or metal, they can also be reflective or light-absorbing in nature, sometimes they can only be distinguished by color. These are traditionally not the easiest of target components for 3D camera imaging.

"The challenge for us in extending our product portfolio and developing a Pickit solution specifically for such small- to medium- sized parts was finding a 3D camera that provided the higher level of performance we just had to have and which assured the reliability that all manufacturing customers demand."

He continued, "It’s very important to understand in all of this that bins of small parts for example are just not stable, predictable places. They represent a completely random picking challenge. Picking as a result is very much a non-deterministic process."

"The challenge for us then in meeting new customer expectations for cycle times and picks-per-minute for smaller, even more complex parts is making sure our products deliver the best possible capability in terms of accuracy, decision-making and speed of response. Only then can we assure the reliability that manufacturing scenarios need to be certain of."

Peter Soetens

CEO of Pickit

Following an extensive appraisal of alternative high accuracy 3D cameras, Pickit selected the Zivid One+ Medium camera to begin extending its range of off-the-shelf vision-guided robot solutions to cover smaller, more complex part picking and placing applications. Pickit’s new robot solution would be called Pickit M-HD.

In keeping with the 3D cameras already being used on Pickit’s existing part-picking solutions, the Zivid One+ Medium 3D camera is also based on the structured light measurement technique, thereby avoiding the technical limitations of time-domain (time of flight) and other spatial-domain (stereo vision and laser triangulation) based types.

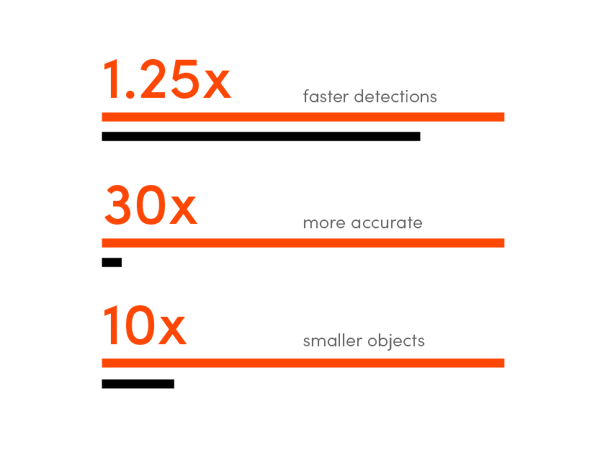

In terms of its technical specifications, the Zivid One+ Medium provided enhanced camera attributes and improvements like higher resolution, speed and color to the new Pickit solution. The launch provided 1.25x faster detections, 30x more accuracy, and detecting 10x smaller objects.

To simplify camera to industrial computer connection, the camera is supported by Zivid Studio, a free tool and user interface which displays the actual 3D image, point cloud and height map direct from the camera. Preconfigured APIs provide an interface for most machine vision software, operating systems and programming languages including C++, C# and .NET.

In order for Pickit M-HD to derive the maximum benefit from the technical advantages offered by Zivid’s high definition 3D camera, Pickit took the strategic decision to introduce a second-generation processor and machine vision software.

The more powerful Pickit 2.0 rack-mounted processor featured a separate GTX graphics card and a 20% faster CPU, with Pickit 2.0 software providing a future-proof platform for all further product updates.

In terms of operation, the robot teaching methodology for the new M-HD solution remains completely consistent with Pickit’s two lower resolution products. In simple terms it’s an easy 3-step process:

Pickit M-HD was released to market in October 2018.

By developing its first high-definition vision-guided robot package around the Zivid One+ Medium 3D camera, Pickit was able to introduce an off-the-shelf product delivering 30 times greater accuracy than preceding lower definition solutions. The Pickit M-HD can detect parts that are 10 times smaller, and with a 25% faster detection speed.

Soetens commented,

Zivid One+ Medium proved itself more than capable of providing the optical performance we needed. In terms of signal to noise ratio, its color acquisition and image resolution, it really is best in class. Importantly, it has helped ensure we keep our promise to provide off-the-shelf machine vision robots that are both ultra-reliable and very easy to use.

Combining a new high-speed rack-mounted processor unit, upgraded state-of-the-art machine vision software and Zivid’s high definition 3D camera, Pickit’s third ground-breaking product has succeeded in attracting an even broader audience to applying easy-to-teach robots in smaller, more flexible, collaborative robot cells.

Soetens added, "We aim to remain ‘best in breed’ in the whole area of automated pick-and-place and we believe that the introduction of the Pickit M-HD helps us achieve that. We do need to be mindful though of even greater challenges ahead, as manufacturers realise the true benefits to be gained from even wider application of machine vision and safe artificial intelligence."

Optimised picking needs to be matched in performance terms by optimised placing for example, and so there’s plenty of scope yet for machine vision robots to make further improvements in this regard and achieve even faster overall cycle times. Solving complex manufacturing problems, which in-turn improves the quality of workers’ lives, is a worthy objective for us all. Smarter, more human-friendly machine vision-guided robots will continue to help us do just that.

Pickit is the 3D robot vision solution that guides your robot to pick and place a wide range of products to automate your processes in a flexible way. → www.pickit3d.com

Zivid brings

Gjerdrums

N-0484, Oslo

Norway