Company

Pandia 3D

Application

Quality assurance

Inspection

Features

Robot-mounted 3D vision for robotics

3D color (RGB)

Quality control at the touch of a button

Free positioning of components in scanning area

Complete geometry check with CAD or reference scan

Learn to use in minutes

3D camera

Zivid 2 industrial 3D color camera

Zivid One+ industrial 3D color camera

Quality assurance and control is a stage in every manufacturing process. If defects and faults are left undiscovered, they always lead to greater cost of rectification, and in turn greater waste. There are almost unlimited opportunities to perform quality inspection in production processes, many are still carried out by humans. The systems that do exist are complex and have prohibitive cost. An accessible, easy to use quality assurance system employing 3D machine vision would alleviate the challenges of controlled quality and in turn reduce waste and failures.

Pandia 3D Pure is designed for simplicity and ease-of-use, such that anyone can inspect parts using high-quality 3D vision. just drop your part down and with the press of a button, inspect it, simple as that. Pandia Pure runs in a browser so avoids many of the installation issues of a separate install. It is democratizing complex 3D inspection for all.

High-fidelity quality inspection systems using 3D machine vision have been available for sometime. But their expense and complexity have been a considerable barrier to entry. The systems that were available were understandably designed primarily to fulfill the requirements of large volume driven organizations. Most of the assembly and manufacturing happens at smaller companies often with high mix/low volume parts.

The accessibility and flexibility of Pandia Pure is bringing very high-fidelity quality inspection into the realm of any company that needs this in the process. Pandia Pure has finished its first few deployments across diverse use-cases for different companies and has left customers delighted that they can inspect and ensure their production standards are right up there with the biggest organizations, at a fraction of the cost and with no specialist expertise needed.

For our Pure quality assurance inspection product, we needed very high-quality 3D vision that we could rely on. With Zivid 3D cameras we found a machine vision product that delivers comparable results of 3D vision sensors at much higher price points.”

Tristan Kenneweg, Founder and CEO of Pandia 3D

Pandia 3D was founded a little over a year ago, he realized that there was a gap in the market for a high-quality quality assurance inspection solution for a range of applications and industries that was affordable and accessible to all. Very high-fidelity inspection systems were available for production quality inspection, but they were complex and out of the affordability range of smaller enterprises. From there Tristan and his team went about developing the Pure software solution to deliver a quality assurance product that works with a range of 3D cameras and sensors. In the last year they have been working with customers in various industries large and small to deliver high-quality inspection that is adaptable for many use-cases and very easy to use with a single button click.

The major challenge for high-quality 3D inspection has historically been access to the technology. With the Zivid 3D industrial color cameras, this technology is now affordable by anyone. The integration with the Zivid One+ and Zivid 2 3D cameras was a straightforward affair with no notable difficulties. Pandia 3D found the Zivid SDK API very user-friendly and smooth to work with.

“We have delivered a high-quality inspection solution that is super simple to use for anyone. The simplicity of use of Zivid 3D cameras helped us achieve that.”

Tristan Kenneweg

Founder and CEO of Pandia 3D

The Pure inspection solution is highly flexible. It can be deployed with the 3D camera stationary or mounted on the arm of a robot and supports Zivid 2 and Zivid one+ industrial 3D cameras in addition to other 3D sensor vendors. In the most straightforward configuration, the 3D camera is set up to cover an area where inspection can be carried out. The part to be inspected is simply placed in the scanning area easily put down and it is a simple button-press to take a high-resolution 3D capture and inspection of the part. The part can be moved to create more complete captures taking in the sides of the part also. No markers are needed to do this and a part of Pandia 3D’s unique value is the ability to take multiple captures of the part from different viewpoints and stitch them together to get more complete coverage of the part.

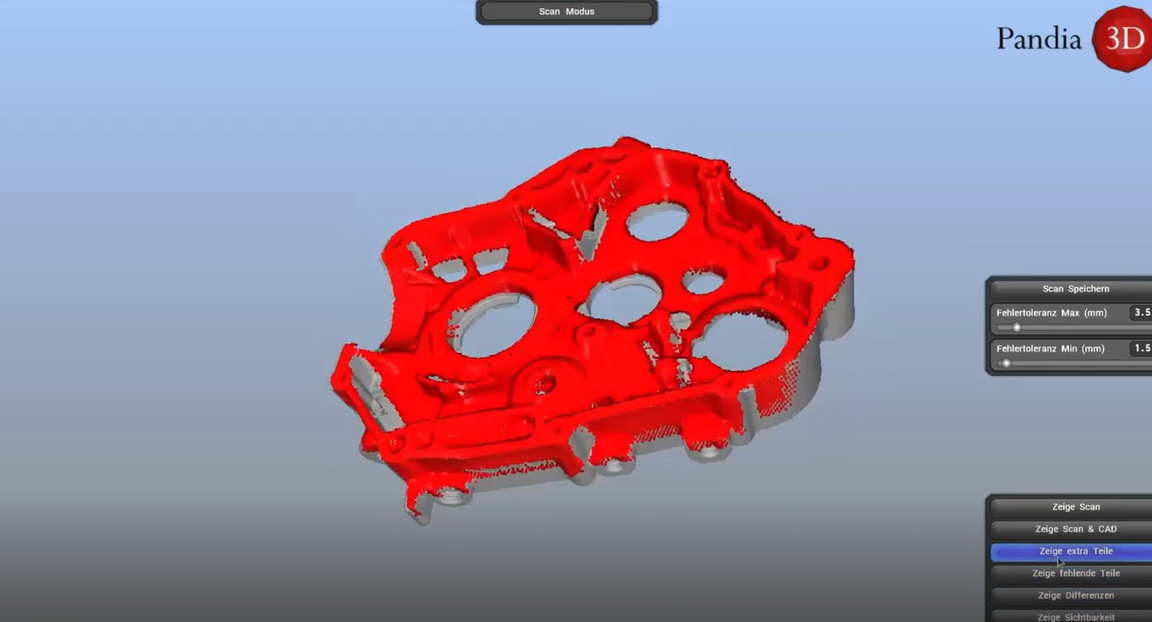

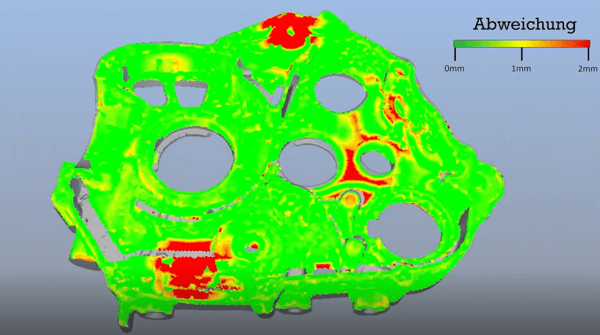

View of Pandia Pure software

View of Pandia Pure software

The result is a well-featured quality assurance solution. It offers super-simple user in-browser operation without local installs and new users are up and running in minutes. Complete geometry checks can be based on reference scans or using CAD models. By using Zivid 3D quality assurance based on color information is also possible. Parts and components can be placed freely, scanned, and inspected. This product is also designed to seamlessly integrate into existing factory systems with and open API. Finally, Pandia Pure together with Zivid 3D cameras bring a very high-quality assurance inspection capabilities to anyone at a very competitive price point

Pandia 3D is young and ambitious German company who have found an important niche to fill in the world of automated quality inspection. Founded by three founders, Tristan Kenneweg, Pius Finkel and Tim Staudenraush, they have a vision to democratize high-quality inspection that anybody can use, for any part. With their Pure quality assurance system, they are focused on making expensive quality issues a thing of the past by enabling customers to inspect with high accuracy and to do it reliably with cost-effectiveness.

Zivid brings

Gjerdrums

N-0484, Oslo

Norway