Company

RoboTire

Application

Automated tire and wheel changing

Features

Robot-mounted 3D vision for robotics

AI

Ease-of-use

3D camera

Zivid 2 M70 - industrial 3D color camera

Published

3 Jan 2023

Tire-changing is hard work. The manipulation and removal of tires are cumbersome and can easily lead to damage to the car or the wheels when executed by humans. An automation system must have an accurate, high-quality vision that can cope with different wheel types and environments.

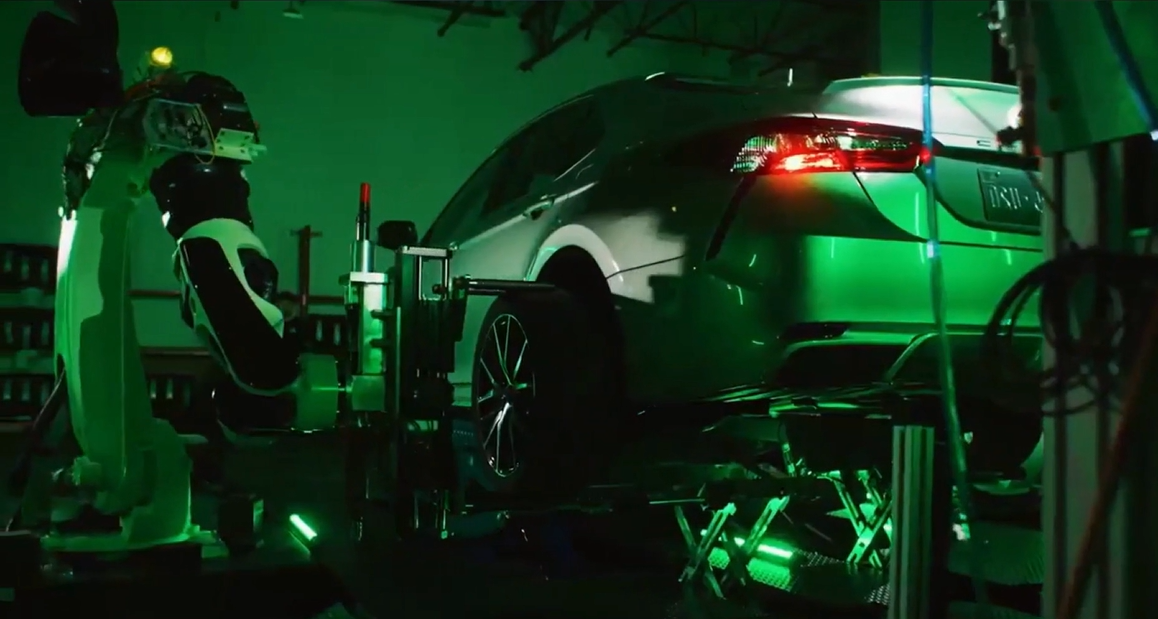

Industrial robots take the heavy lifting out of the equation, and with the Zivid 2 3D camera mounted on the robot, it can capture the scene with the visual detail and depth acuity it needs. RoboTire’s advanced AI algorithms make the system fully autonomous and can adapt to all types of vehicles it encounters.

RoboTire is disrupting the automotive industry; the change of tires has been carried out the same way since the car’s arrival. Now, Robotire’s autonomous solution is paving the way across North America for a new solution. For fleets and auto repair service providers, RoboTire has made the world of vehicle maintenance easier.

This system encounters a huge array of different situations with different vehicle types with different wheels and tires. Shiny, metallic wheel nuts are about the most challenging thing for a 3D sensor. Zivid 2 performs admirably in the face of such uncertainty.”

Benjamin Wilson, Operations Senior Manager of Robotire

Victor Darolfi is the CEO of RoboTire and has a long track record in engineering manufacturing and working to improve process efficiency at companies such as Lockheed Martin. While having the tires changed on his car some years back, he drew on his experience to see how greater efficiency and better safety could be brought to the common task of changing tires. He recognized that the current state of robotics, AI, and 3D machine vision was at a point where a new solution was possible. He also saw that if executed correctly, it would change and improve the industry in a truly disruptive way.

The challenges were plentiful but possible to solve. The operation of removing and replacing tires seems a straightforward task, but there are a lot of variables that an automated system needs to be able to handle. The system faces an almost endless range of vehicles, wheels, fastening nuts, and tire locations. It would need a mobile set of eyes on the robot itself to account for all the combinations it would encounter, meaning a robot-mounted 3D camera or sensor. It would also need millimeter-level accuracy to locate wheel nuts and remove them without risking damage to the rims or nuts. It then has to come in at the proper angle, within a fraction of a degree to remove the wheel from the vehicle. Not only must the system do the entire removal, but then it also has to put the new tires back on the vehicle, accurate to a millimeter or submillimeter location, within a fraction of a degree in placement in angle. For this, accuracy is king. Last but not least, the system would need to be highly adaptable and autonomous with minimum operator intervention.

“Because of the challenges this task presents, we needed a 3D sensor that could maintain a high degree of calibration fidelity and could re-calibrate simply and efficiently. Zivid 2 provides this.”

Benjamin Wilson

Operations Senior Manager of Robotire

RoboTire chose the Zivid 2 industrial 3D camera as their vision solution. This centered around the need for extreme accuracy and an ability to handle a vast variety of scenarios. It necessitated a 3D machine vision system that was designed to excel whilst mounted on the robot’s arm and always produce top-notch results. As the tire-changing scenarios the system had to cope with had so many variables, they had to have very detailed high-quality point clouds. In addition, the wheel nuts presented one of the biggest challenges in industrial machine vision, how to capture detailed high-quality point clouds from shiny metallic parts. The Zivid 2 3D camera had the high dynamic range (HDR) capabilities to meet this challenge with a dynamic range of over 100 dB.

Robotire's wheel-changing system with a Zivid 2 3D camera

Another factor was the calibration stability of the 3D camera. There is a lot of temperature variation with bay doors opening and closing temperature variations and vibrations would be commonplace. These are all things that will make a 3D sensor system drift if it isn’t designed to cope with such conditions. Fortunately, Zivid 3D cameras are called industrial for a good reason as Zivid design, build, and test each one for calibration resilience, and stability. RoboTire uses advanced AI as a part of its part recognition system for locating the wheel nuts and that AI relies heavily on the accuracy and consistency of the images and point clouds it receives from Zivid 2.

The system from RoboTire is proving itself with great success on its first deployments. Operators can now focus on other valuable tasks and leave the heavy lifting to the automated tire-changing system from RoboTire. The typical time it takes for the system to change four tires on a car is under 20 minutes, which is very comparable to how fast a human could do it. But perhaps most importantly, this system provides a level of accuracy and repeatability that humans cannot match. Damage to wheel nuts and cross-threading on the vehicle's hubs is a common problem with human operation. When this happens the damage can involve a brand-new wheel unit which is a considerable unexpected expense and inconvenience for the consumer. The RoboTire system practically eliminates this possibility, leaving happy customers and tire shops alike.

RoboTire is a robotics and automation solution that is revolutionizing the way tires are changed. Founded by CEO Victor Darolfi in October 2018, RoboTire has designed a system that enables robots to change tires in a fraction of the time human operators can—reducing an hour-long experience down to under 15 minutes. By bringing innovation to the traditional, RoboTire is transforming the way fleet operators, dealers and independent service providers look at tire and wheel services. For more information about RoboTire, visit robotire.com. RoboTire was founded in Plymouth, Michigan in 2019. With a vision to develop and deploy robotic systems and tools that service vehicles more safely and faster than ever.

Zivid brings

Gjerdrums

N-0484, Oslo

Norway