3D Vision Technologies Compared

Can you see the difference?

Compare what matters

Point cloud quality is essential when evaluating 3D cameras for a project. Compare the performance of Zivid with another structured-light 3D camera widely used in automation on what truly matters and why Zivid wins:- Excellent 3D data coverage

- Reliable performance in production

- Flexible robot-mount integration

Excellent 3D data coverage

Missing or incomplete 3D data can lead to collisions, damaged parts, poor path planning, and the robot's inability to detect all objects and empty the bin. Holes in the point cloud, distortions, and occlusions often cause robots to make critical mistakes. Accurate, true-to-scale point clouds are essential for generating reliable pick poses in robotic manufacturing.

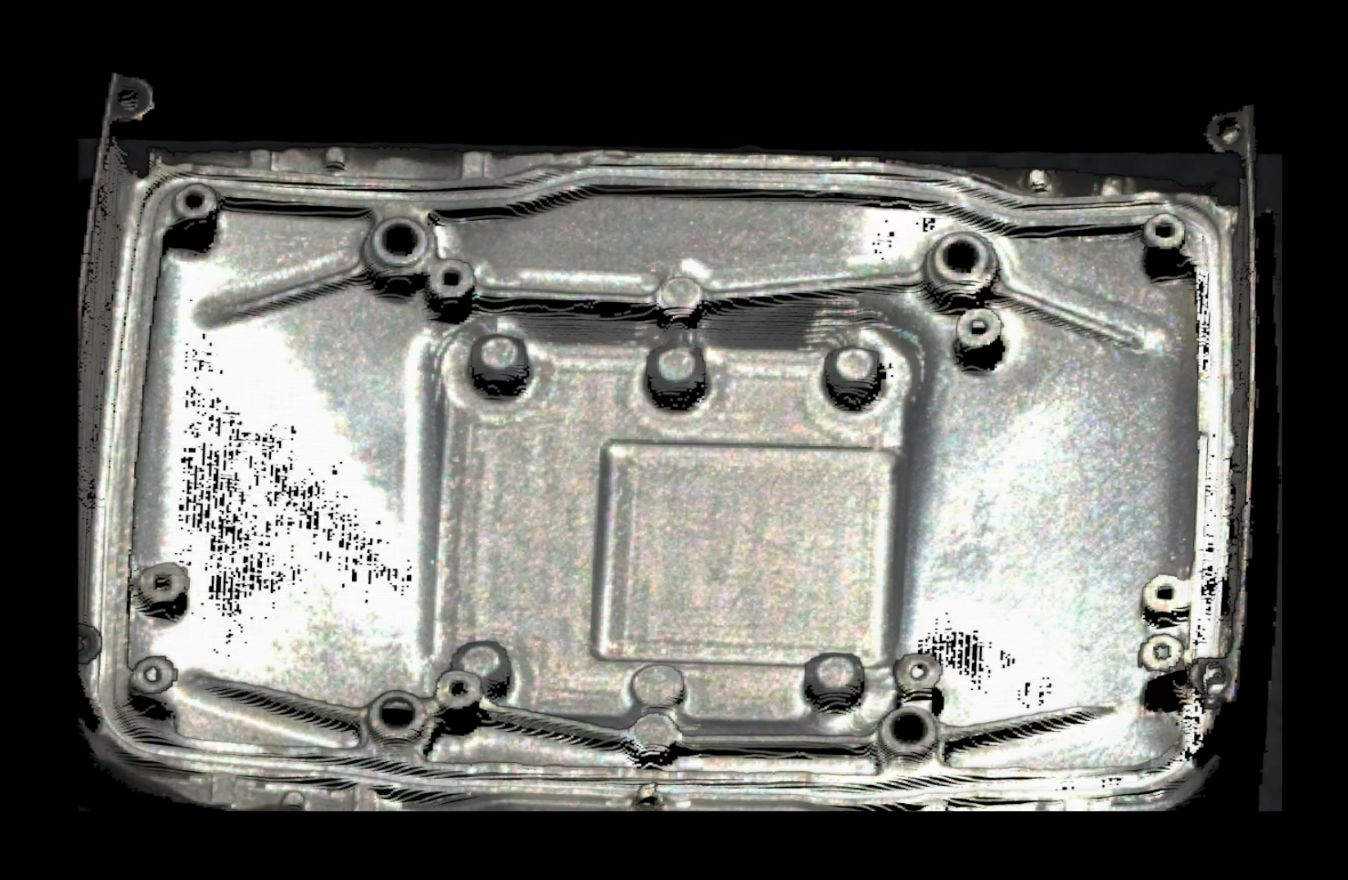

Side-by-side camera comparison of various metallic parts in a bin (700 lux)

Zivid

Structured-light camera alternative

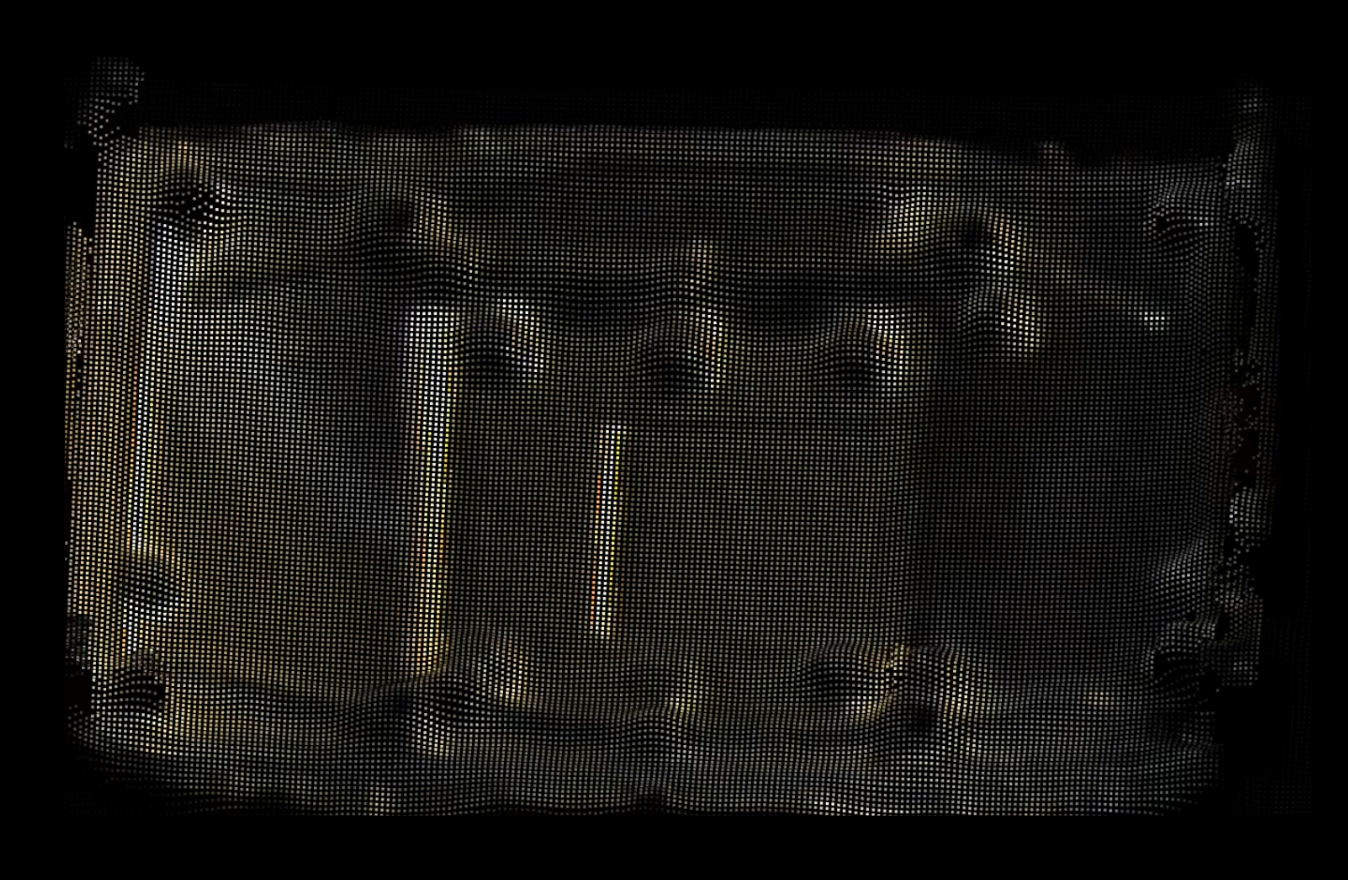

Side-by-side camera comparison of a metal object with holes (100 lux)

Zivid

Structured-light camera alternative

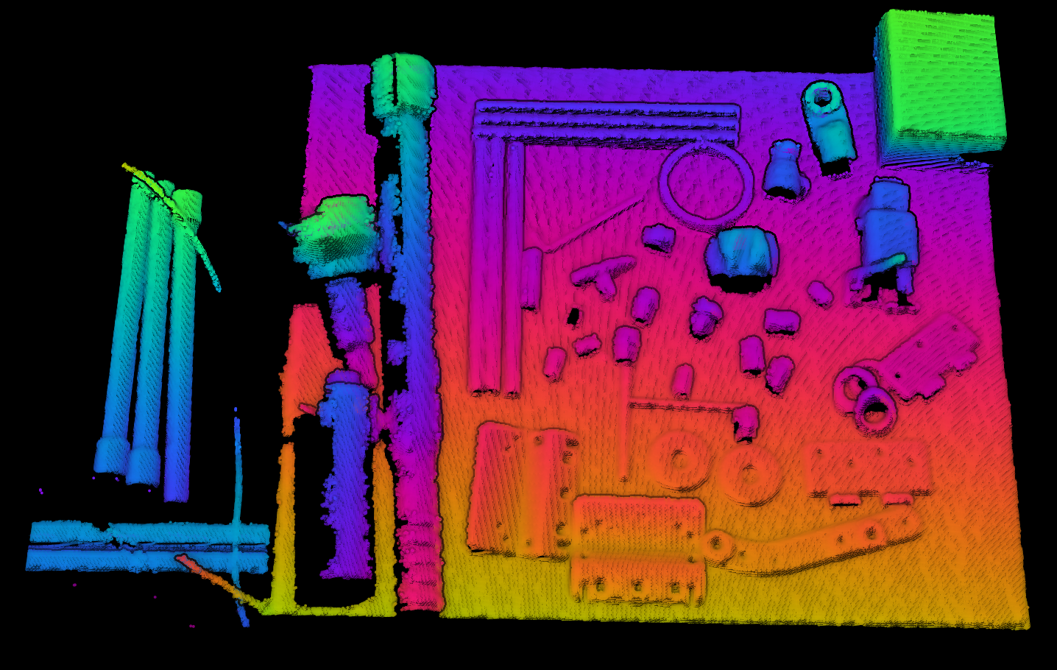

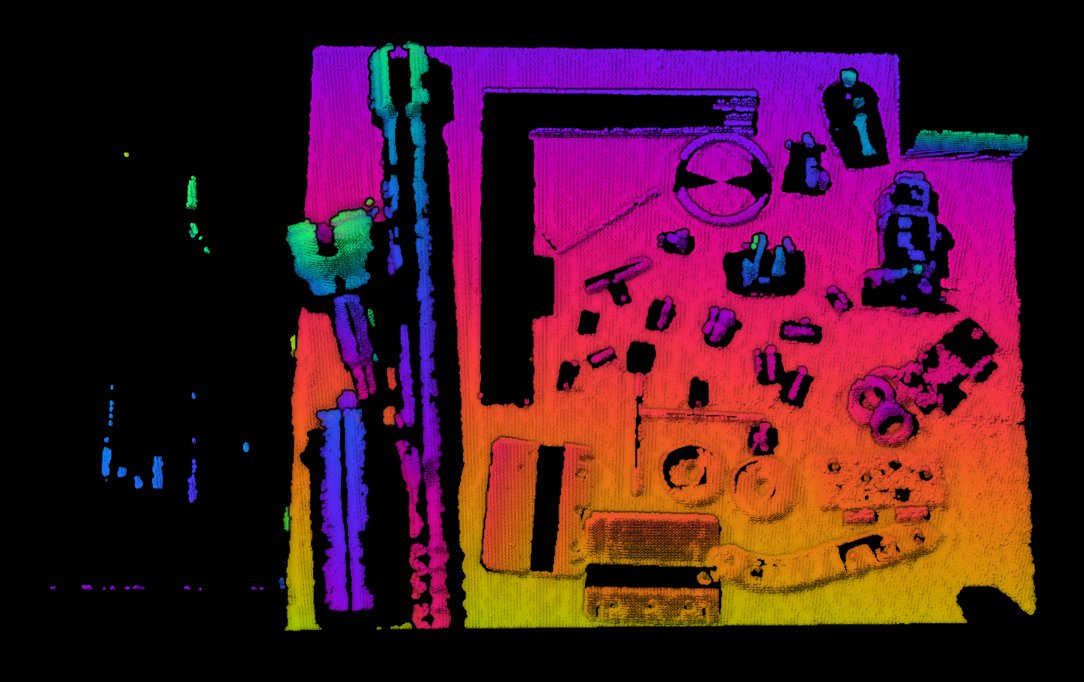

Side-by-side camera comparison of various shiny parts (depth coloring - 5000 lux)

Zivid

Structured-light camera alternative

Zivid 3D cameras deliver dense, precise point clouds—even when imaging challenging materials like black plastics, shiny metals, or complex shapes. Powered by patented High Dynamic Range (HDR) technology, they capture fine details across a wide range of object sizes and arrangements, ensuring outstanding coverage even in the most demanding scenes.

Zivid 2+ 3D point cloud quality

| Parameter | Details |

| Resolution |

5 megapixels XYZ, RGB, SNR |

| High dynamic range |

max 129 dB for HDR acquisition |

| Point precision |

80 microns |

| Trueness |

> 99.8% |

| Capture time |

910 ms for detailed and small features |

Reliable performance in production

Even minor changes in temperature, vibration, or ambient lighting can significantly affect 3D vision performance due to calibration drift. While many 3D cameras work well in controlled lab environments, real-world conditions—like those found in warehouses and factories—demand robust, reliable performance.

|

Zivid → |

|

|

|

|

Structured-light camera alternative → |

|

|

|

Zivid cameras are factory-calibrated for long-term stability and built to endure harsh industrial environments, including extreme temperatures, shocks, and vibrations. Each unit is thoroughly tested to ensure consistent accuracy, prevent overheating, and sustain performance over tens of millions of point cloud captures. With Zivid, fewer components fail—enabling a more dependable system design.

Zivid 2+ industrial build quality

| Parameter | Details |

| Accelerated lifetime testing |

+5000 hours of operational testing for each camera |

| Tested for harsh environments |

15G shock, 5G sinusoidal, over-temp, over-wattage, over photon exposure |

| Pre-delivery tests |

100+ hours of arduous performance, reliability, and calibration tests |

| Ultra-compact form-factor |

169 x 124 x 56 mm³ |

Flexible robot-mount integration

Zivid 3D cameras are designed for both stationary and robot-mounted use. Their compact, short-baseline design reduces blind spots, occlusions, optical singularities, and point cloud artifacts. Robot mounting expands possibilities for applications that require accurate, close-range imaging with a wide field of view. This allows us to put the camera at a relatively short distance where the accuracy and precision are great.

In contrast, 3D cameras with larger baselines can restrict robot movement, increase the risk of collisions, and add unnecessary payload. These designs may also suffer from unstable calibration and require frequent adjustments, as they’re not built with robot mounting in mind.

A large baseline - loss of scene details, creating holes, and missing data

Zivid 3D camera with a smaller baseline - Fewer occlusion outliers

At Zivid, we pride ourselves on being a pure-play 3D camera company—fully dedicated to developing fast, accurate, industrial-grade 3D color cameras that address core automation challenges. We actively seek collaboration with vision system integrators and automation solution providers to bring smarter, more reliable vision to the factory floor.

Book a demo

Want to know what Zivid can do for you? Schedule a personalized demo with our vision engineers.

Exploring Manufacturing Applications with Advanced 3D Vision

In this hands-on demo, our vision engineer tests the Zivid 2+ MR60 camera across real point cloud scenes in manufacturing, from inspection and robot guidance to bin picking.