Company

Inos Automationssoftware GmbH

Application

Automated palletizing and depalletizing solution

Features

Turn-key palletizing and depalletizing solution

Automation of logistics processes

High-quality 3D machine vision

Item localization and segmentation software

Data analytics and process monitoring

3D camera

Zivid 2 M70 - industrial 3D color camera

Published

16 Oct 23

In various industries, including automotive manufacturing, the task of depalletizing and handling goods is crucial but often labor-intensive. The demand for efficiency has grown, especially amidst labor shortages. This is where the integration of robots equipped with advanced 3D machine vision comes into play. Automotive production involves a constant influx of materials, demanding a swift yet precise depalletizing process.

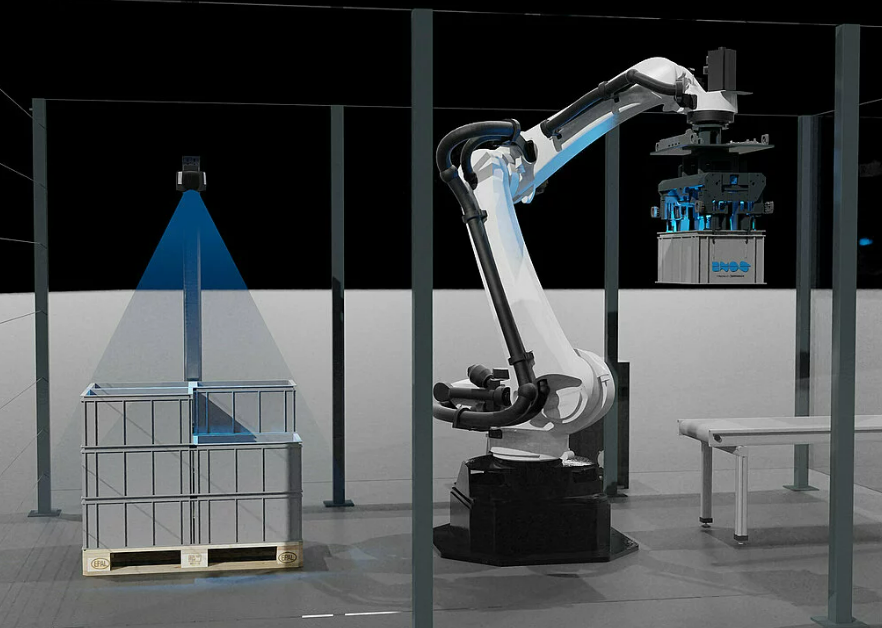

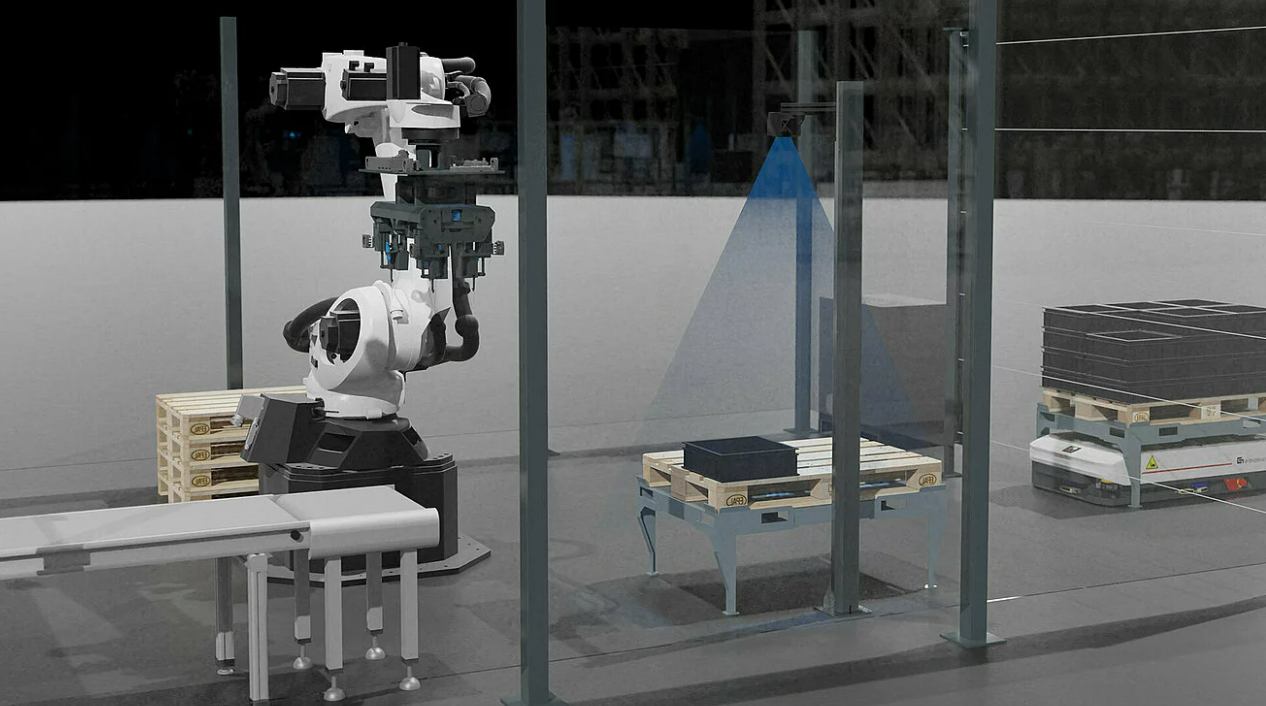

This solution is a turn-key robot cell, dedicated to automated palletizing and depalletizing of KLTs in automotive manufacturing as well as other industries. Using the Zivid 2 M70 industrial 3D camera, the robot can reliably detect KLTs of the standard sizes according to VDA4500 for fully automatic placement on conveyors, automated guided vehicles (AGVs), pallets, or other targets for further item processing.

The inos KLT-handling solution is already finding successful deployment with major automotive manufacturers and suppliers. It offers several benefits for efficient depalletizing by reducing the risk of bottlenecks, downtime, and related costs.

Zivid 2 M70 gave the speed and coverage for us to reliably depalletize a full pallet. It also captures at high speed meaning we can run the system at a speed that matches other processes without adding delays.”

Alexander Beck, Head of Operations, inos Automationssoftware GmbH

The depalletizing and handling of goods is integral to many industries, from e-commerce to manufacturing. Automotive production is an example of such an industry. The pace of incoming materials and parts can be fast, but it is often heavy and difficult work for humans to carry out. It is an ideal scenario for using robots equipped with 3D machine vision.

The system needs to be adaptive and flexible. The pallets will not always be loaded up in a structured manner, so the machine vision must be able to detect and segment the parts accurately for a successful picking operation to happen. The main challenge is having a field-of-view (FOV) that is both wide and deep enough to cover the working area in question. Robot cycle times must also match the needs of the operation and the machine vision must be fast enough that it doesn’t act as a bottleneck for the robot’s speed. Inos' intelligent automated depalletizing solution provides a highly reliable, high-performance solution for this challenge.

Inos turn-key solution

Automotive production involves a constant influx of materials, demanding a swift yet precise depalletizing process. The manual handling of heavy items poses risks, and with current labor shortages, this task has become even more challenging. The goal was to develop a solution that not only streamlined the process but also reduced the strain on human workers.

In terms of technical challenges, this task was quite straightforward as the boxes to be picked from the pallet are usually quite large size. The top challenge was being able to accurately segment the items so that they were picked from the center of gravity and picked at a rate that was fast enough for the next stage of the process. Those challenges can be met with the right industrial robots and a high-quality 3D machine vision system, such as those provided by inos and Zivid.

“Our automated palletizing and depalletizing solution enables our customers to streamline their logistics processes allowing them to produce more at higher quality.”

Alexander Beck

Head of Operations, inos Automationssoftware GmbH

This solution is a turn-key robot cell meticulously designed for the automated palletizing and depalletizing of KLTs (Kleinladungsträger, a standard container in automotive manufacturing) not only in the automotive industry but also in various other sectors. Central to the success of this innovative system is the integration of the Zivid 2 M70 industrial 3D camera. This state-of-the-art 3D camera plays a pivotal role in ensuring the efficient and precise detection of KLTs, in strict adherence to the VDA4500 standards.

The system's core functionality is its ability to fully automate the placement of KLTs on conveyors, automated guided vehicles (AGVs), pallets, and other predefined targets. This automation enhances the overall material handling process, reduces human intervention, and minimizes the risk of errors. The robot, armed with the Zivid 2 M70 camera, performs these tasks with incredible speed and accuracy.

The inos KLT-handling solution is gaining traction with leading automotive manufacturers and suppliers, delivering a host of advantages for efficient depalletizing. It significantly minimizes the risk of bottlenecks and costly downtime in production processes.

The purchase of automated KLT handling is an investment in the future, freeing up labor for more complex tasks. It puts a tick in the box for better productivity and smoother operations across manufacturing use cases in automotive. Importantly, the inos solution's adaptability extends beyond the automotive sector. It proves valuable in various manufacturing scenarios, making it a versatile and cost-effective investment for a range of industries.

inos is a highly specialized vision expert and partner within the Grenzebach Group and supports customers with innovative image processing and laser technologies. The company, headquartered in Stuttgart, Germany, coordinates projects worldwide for customers in the industries of automotive, metal, white goods, intralogistics, and the international Grenzebach Group. The image processing and laser technologies of inos offer efficient, sustainable, and intelligent system solutions along the entire value chain. Standardized and customer-specific applications are technologically supported in future fields such as artificial intelligence, deep learning, and machine learning.

Zivid brings

Gjerdrums

N-0484, Oslo

Norway